-

Locating Pins and Heating Rods for Spline Test Molds

In the material R&D and quality control of key fields such as aerospace, automotive manufacturing, and high-end equipment, spline test molds are critical for obtaining core data including material

2025/10/25 hooren

-

Technical Guide to Composite Material Specimen Test Molds and Metal Powder Specimen Test Molds Hoorenmold

In material performance testing, key indicators of composites and metal powders require precise evaluation via standard spline testing. Composite material spline testing molds and metal powder spline

2025/10/24 Spline test mold

-

Tensile Test Molds for Injection Molding Machines and Vulcanizing Machines Hoorenmold

As core tooling for material performance testing, tensile test molds directly determine the detection accuracy of key indicators such as tensile strength, flexural strength, and hardness of polymer ma

2025/10/23 Tensile Test Molds

-

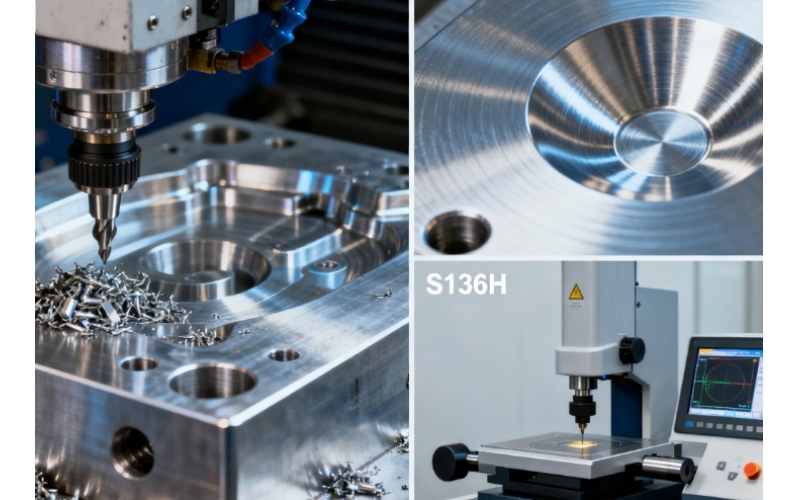

Polishing Spline Test Molds and Nitrided Spline Test Molds HoorenMold

In the field of material testing and precision manufacturing, spline test molds serve as core equipment for verifying material mechanical properties, molding quality, and working condition adaptabilit

2025/10/22 Spline Test Molds

-

Stainless steel spline test mold steel spline test mold Hoorenmold

1. Core Functions and Executive StandardsThe stainless steel specimen test mold and mold steel specimen test mold are core tools for metal material performance testing, specifically designed to fabric

2025/10/20 Spline test mold

-

Technical Specification and Application Guide for Single-Cavity and Multi-Cavity Specimen Test Molds

Definition and Core Functions: Specimen test molds are key equipment in material performance testing. They precisely simulate actual production molding processes to produce test specimens complying wi

2025/10/18 Spline test mold

-

Tensile and Impact Spline Test Molds: Precision Tools for Material Mechanical Property Testing

In the field of material mechanical property testing, tensile spline test molds and impact spline test molds are core tooling for ensuring test data accuracy and standardizing material quality control

2025/10/17 Spline test mold

-

Technical Practice of Rubber Electrical Performance, Tear Strength and Dielectric Performance Test Molds

With the continuous increase in requirements for extreme environmental resistance and performance stability of high-end rubber products, rubber electrical performance test molds, rubber tear strength

2025/10/16 Rubber Test Molds