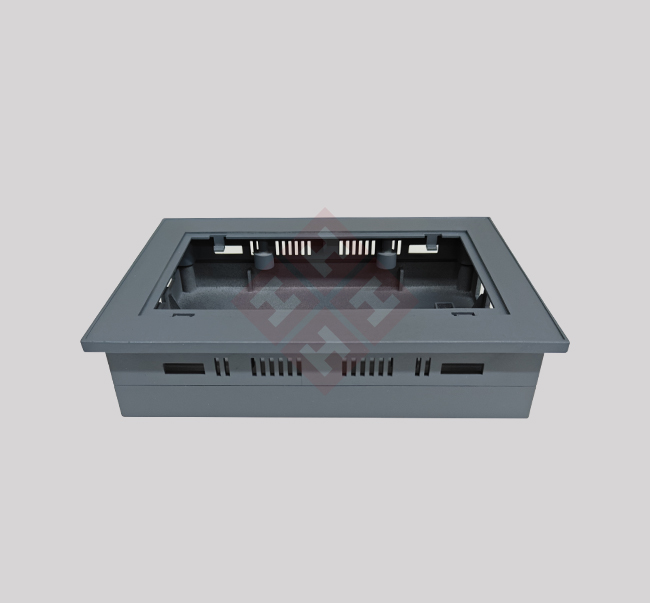

Electronic instrument shell injection mold is an important tool for the production of electronic instrument shell.

Mold structure

1, cavity and core: the cavity is the part of the mold used to form the external shape of the electronic instrument housing, and the core is used to form the internal shape. The cavity and core are usually made of steel and are precisely machined to ensure dimensional accuracy and surface quality.

2, the pouring system: the pouring system includes the main channel, diversion channel and gate. Its role is to introduce the molten plastic material into the cavity, ensuring that the plastic evenly fills the entire mold.

Design points

1, material selection: commonly used mold materials are steel, aluminum alloy and so on. Steel with high strength, high hardness and good wear resistance, suitable for mass production; Aluminum alloy has a relatively light weight and good thermal conductivity, suitable for small batch production or rapid mold manufacturing.

2, mold accuracy: Electronic instrument housing usually has high dimensional accuracy and surface quality requirements, so the accuracy of the mold is crucial. The machining accuracy of the mold should be controlled within a certain range to ensure that the molded product meets the design requirements.

Manufacturing process

1, processing method: Mold manufacturing usually adopts mechanical processing, electric discharge machining, wire cutting processing and other methods. These processing methods can achieve high-precision mold manufacturing and ensure the dimensional accuracy and surface quality of the mold.

2, heat treatment: In order to improve the hardness, strength and wear resistance of the mold, it is usually necessary to heat treat the mold. Heat treatment methods include quenching, tempering, nitriding, etc.

3, surface treatment: In order to improve the surface quality and wear resistance of the mold, it is usually necessary to perform surface treatment on the mold. Surface treatment methods include chrome plating, titanium plating, nitriding, etc.