-

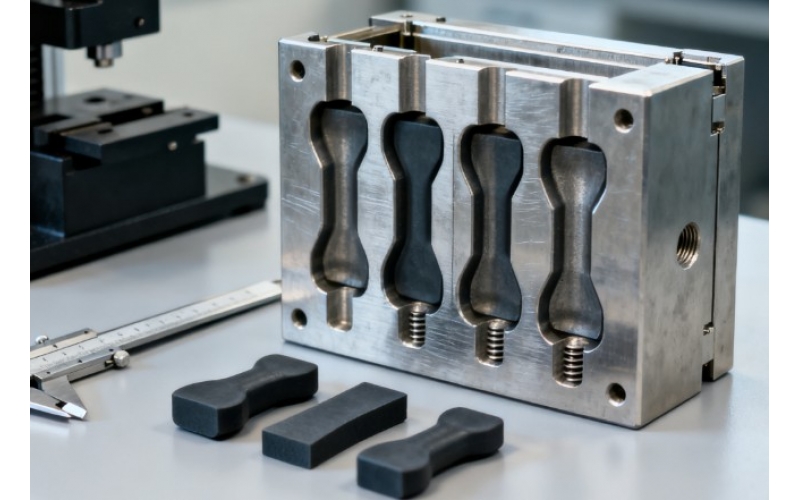

Rubber Tensile Test Molds, Rubber Hardness Test Molds, and Rubber Compression Set Test Molds Hooren Mold

In the quality control and performance verification of rubber materials, rubber tensile test molds, rubber hardness test molds, and rubber compression set test molds are three core types of equipment.

2025/10/08 Rubber Test Molds

-

Detailed Explanation of Injection Molding Process Parameters for PBT Material Molds

1. PBT Material Properties and Preprocessing Specifications1.1 Core Material PropertiesAs a crystalline engineering plastic, PBT (polybutylene terephthalate) offers excellent mechanical strength and h

2025/09/30 Injection Molding

-

How to Achieve Precision Injection Molding of PA66 Glass Fiber-Reinforced Parts

In mainstream manufacturing scenarios like new energy vehicle battery brackets and 5G base station connectors, PA66 glass fiber-reinforced parts are widely used as core structural components due to th

2025/09/29 Injection Molding

-

Material Selection and Performance Analysis of PA Plastic Injection Molds

1. Core Requirements of PA Plastic Properties for Mold MaterialsPolyamide (PA) plastic features strong crystallinity and significant fluctuation in molding shrinkage. Glass fiber-reinforced grades (e.

2025/09/28 Injection Molds

-

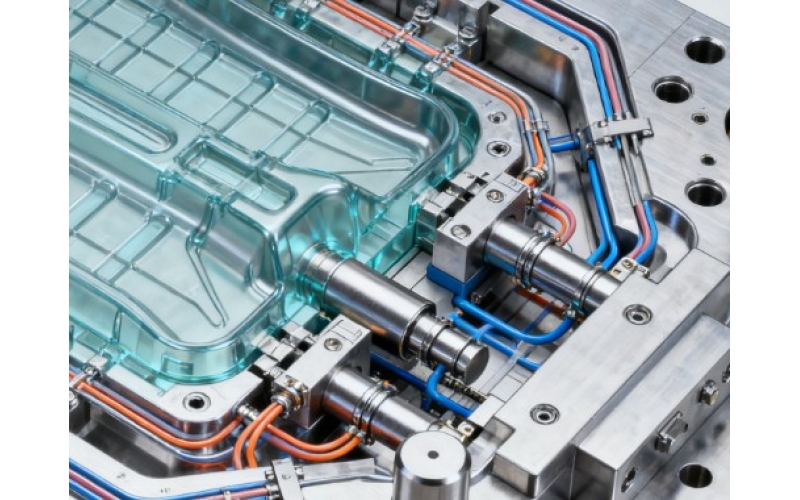

Application of PET Injection Molds in the Food Packaging Industry

Polyethylene terephthalate (PET), a high-performance thermoplastic polyester, is widely used in food packaging due to its excellent transparency, barrier properties, mechanical performance, and recycl

2025/09/27 Injection Molds

-

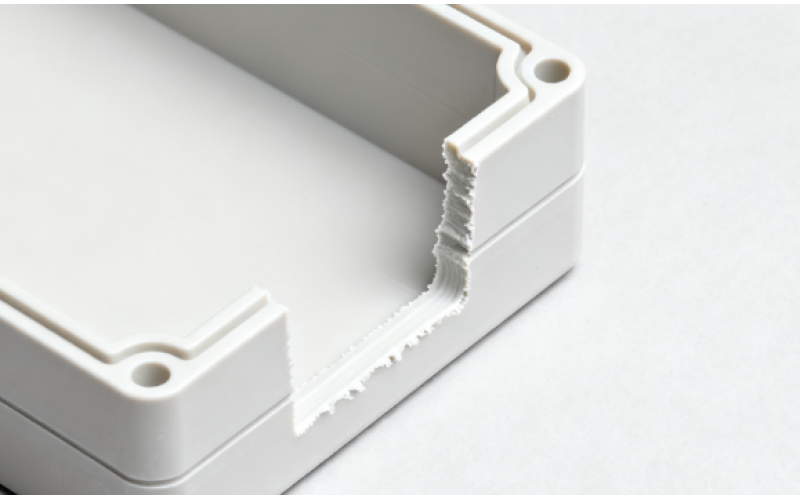

Analysis of 13 Common Defects in PP Injection Molding

1. Short ShotPhenomenon: The product fails to fully fill the mold cavity, with missing parts at corners or thin-walled areas.Causes: Excessively long PP melt flow distance (exceeding the limit flow -

2025/09/26 Injection Molding

-

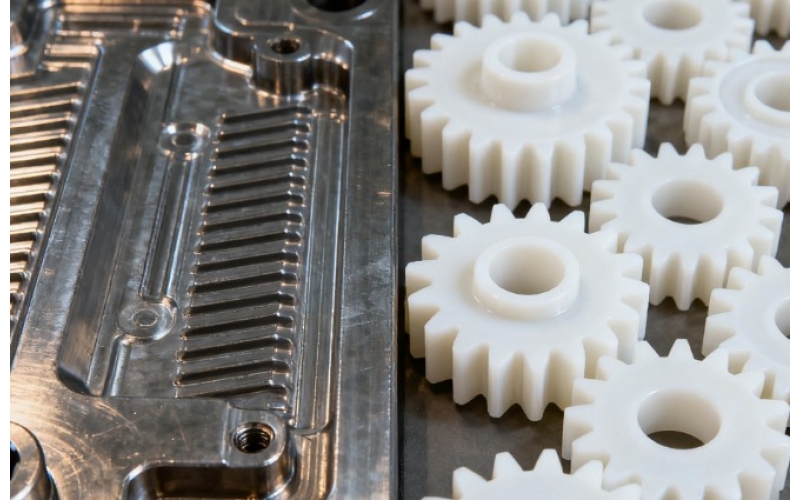

Manufacturing Process and Precision Control of POM Injection Molds

1. Core Mold Requirements Based on POM PropertiesPOM (polyoxymethylene), divided into homopolymer (POM-H) and copolymer (POM-K), is a high-density crystalline engineering plastic with excellent wear r

2025/09/25 Injection Molds

-

Application of PVC Injection Molds in Medical Device Manufacturing

Medical-grade polyvinyl chloride (PVC) has become a core raw material for disposable medical devices due to its good biocompatibility, chemical corrosion resistance, and cost advantages. It is widely

2025/09/24 Injection Molds