Material Selection and Performance Analysis of PA Plastic Injection Molds

1. Core Requirements of PA Plastic Properties for Mold Materials

Polyamide (PA) plastic features strong crystallinity and significant fluctuation in molding shrinkage. Glass fiber-reinforced grades (e.g., PA66+30% glass fiber) are widely used in industry, placing targeted demands on mold materials. Glass fibers notably accelerate mold wear and are the primary cause of surface scratches. Thus, mold materials must match the properties of different PA types to ensure a service life of hundreds of thousands to millions of cycles.

Ordinary non-reinforced PA (e.g., pure PA6, PA66) has basic requirements for molds, which only need fundamental wear resistance and polishability. In contrast, glass fiber or mineral-filled reinforced PA requires mold materials to simultaneously possess high hardness, strong wear resistance, and anti-adhesive wear capability, while avoiding cracking caused by excessive brittleness.

2. Core Principles and Performance Dimensions for Mold Material Selection

2.1 Core Principles of Material Selection

Material selection follows the logic of "matching requirements and balancing costs," with four key prerequisites: product surface precision (e.g., mirror-like smoothness), production volume (small batches usually <10,000 cycles, large batches >500,000 cycles), PA filler type and content, and mold structure complexity. Two pitfalls should be avoided: unnecessary use of high-cost corrosion-resistant steel leading to waste, and premature mold failure due to insufficient material wear resistance.

2.2 Analysis of Key Performance Indicators

2.2.1 Hardness and Wear Resistance

Wear resistance is mainly related to the carbon content, alloy content, and internal grain structure of steel. In practice, a hardness range of HRC52-58 is optimal: below HRC52 (e.g., 718H steel), surface scratches easily occur due to insufficient hardness; above HRC58, material toughness decreases, increasing cracking risk.

2.2.2 Corrosion Resistance and Polishability

When PA contains flame retardants, acidic substances may decompose at high temperatures. In such cases, corrosion-resistant steel with a chromium content of at least 13% (e.g., S136) is required, as its surface protective film significantly reduces corrosion rates. Polishability depends on steel purity; electroslag remelted (ESR) steel (e.g., STAVAX ESR) has fewer impurities, enabling mirror polishing and avoiding pitting defects.

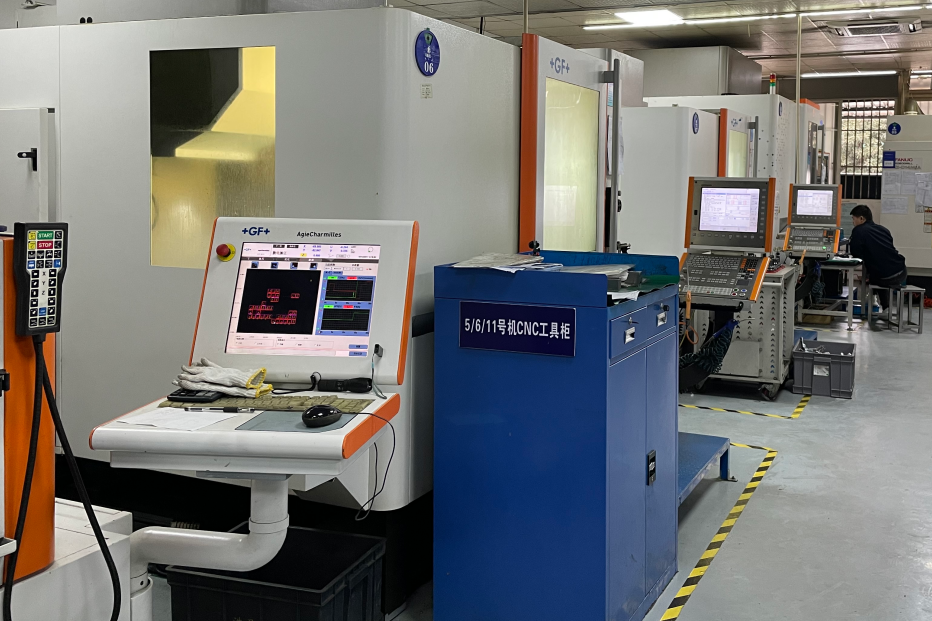

2.2.3 Machinability and Thermal Stability

Unheat-treated general-purpose steel (e.g., P20) has lower hardness, making CNC machining more efficient than wear-resistant steel, but it has poor thermal fatigue resistance. After quenching and tempering, wear-resistant steel (e.g., H13) can withstand the 250-300°C temperature required for PA molding, with a much longer time to thermal cracking than ordinary steel.

3. Classification and Application Scenarios of Typical PA Mold Materials

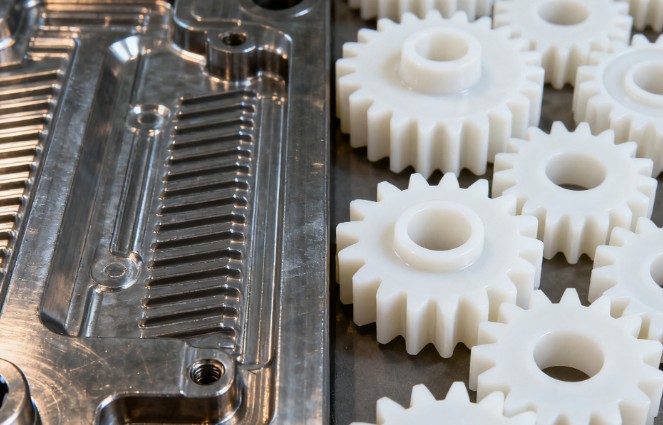

3.1 General-Purpose Materials (Small-Batch Production)

Represented by 3Cr2Mo and 718H, with hardness HRC30-45, they are suitable for pure PA products (e.g., gears, bearings) and meet production needs within 100,000 cycles. These steels have low processing costs but show drastically shortened service life (often <50,000 cycles) when used for glass fiber-reinforced PA, requiring frequent polishing maintenance.

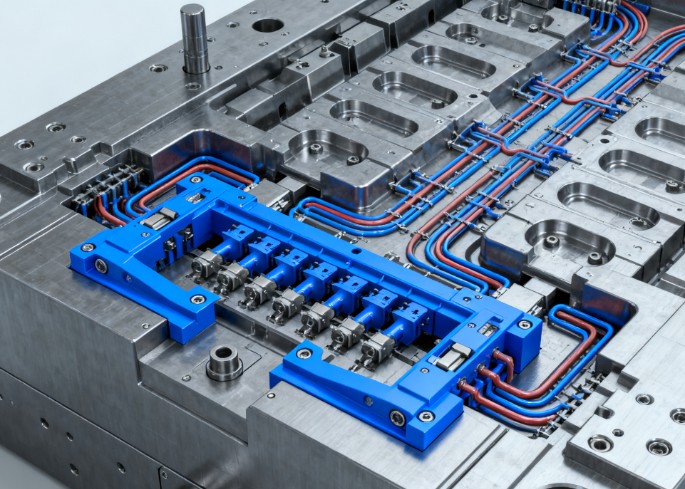

3.2 Wear-Resistant Materials (Large-Batch Reinforced PA)

Typified by H13 and 4Cr5MoSiV1, with hardness HRC52-58, they belong to medium-carbon high-alloy steels. For molds producing PA66+30% glass fiber products, their service life reaches 800,000-1,200,000 cycles, more than ten times that of general-purpose steel. Note that high-carbon high-chromium ledeburite steel should be avoided, as its internal structure easily causes adhesive wear.

3.3 High-Precision Corrosion-Resistant Materials (High-End Products)

Steels such as S136 and STAVAX, with hardness HRC48-52 and good corrosion resistance, are suitable for molds of medical and food-grade PA products (e.g., infusion set connectors). After TD coating treatment, the surface friction coefficient decreases, extending service life to 1,500,000 cycles.

3.4 New Materials and Technologies

3D-printed metal molds (e.g., Maraging Steel 300) reduce weight by over 1/3 through optimized design, shortening trial mold cycles from two weeks to three days. Although their service life is only 100,000-150,000 cycles, they are ideal for rapid iteration of new product development.

4. Material Failure Case and Optimization Scheme

A mold for automotive PA66+30% glass fiber gears initially used P20 steel, showing cavity scratches after only 8,000 cycles, with significantly reduced surface smoothness. Analysis revealed insufficient hardness of P20 steel (only HRC32), failing to resist abrasive wear from glass fiber particles.

The optimization scheme involved replacing with H13 steel, performing vacuum quenching (tempering twice at 550°C) to increase hardness to HRC54, and mirror polishing the cavity. After improvement, the mold operated 600,000 cycles without obvious wear, reducing maintenance costs by 70%.

5. Conclusion

Material selection for PA injection molds should establish a "performance-demand-cost" matching model: general-purpose steels like 718H are preferred for small-batch pure PA production; wear-resistant steels like H13 are mandatory for large-batch glass fiber-reinforced PA; dedicated steels like S136 are used for high-end corrosion-resistant scenarios. By controlling hardness within HRC52-58, selecting appropriate medium-carbon high-alloy compositions, and combining high-quality smelting processes with precise heat treatment, the optimal balance between mold life and overall cost can be achieved.