Application of PET Injection Molds in the Food Packaging Industry

Polyethylene terephthalate (PET), a high-performance thermoplastic polyester, is widely used in food packaging due to its excellent transparency, barrier properties, mechanical performance, and recyclability. As a key tool for producing PET food packaging products, PET injection molds directly determine the quality, production efficiency, and cost of packaging.

1. Properties of PET and Its Advantages in Food Packaging

1.1 Core Properties of PET

PET has biaxial stretching characteristics, delivering superior mechanical performance after injection molding to protect food during transportation and storage. With a glass transition temperature of approximately 70°C and a melting point of 250-260°C, it maintains stable physical form at room temperature and exhibits good moldability during injection processing. Additionally, PET boasts strong chemical stability, resisting degradation in most pH environments common for food, and provides effective barrier against oxygen, carbon dioxide, and water vapor, extending food shelf life.

1.2 Application Advantages in Food Packaging

According to 2024 data from Statista, PET bottles account for 73% of the global beverage packaging market. This is attributed to PET’s high transparency (light transmittance ≥ 90%), which clearly displays beverage color and state to attract consumers. In terms of barrier performance, unmodified PET bottles achieve an oxygen barrier rate of 2-5 ml/(m2·day) and a carbon dioxide barrier rate of 10-20 ml/(m2·day); with coating technology, this performance can be enhanced 3-5 times, preventing beverage oxidation and carbonation leakage. Weighing only 1.38 g/cm3 (over 80% lighter than glass), PET reduces transportation energy consumption by 15-20% and has a breakage rate below 0.1%, improving circulation safety.

2. Key Design Points of PET Injection Molds

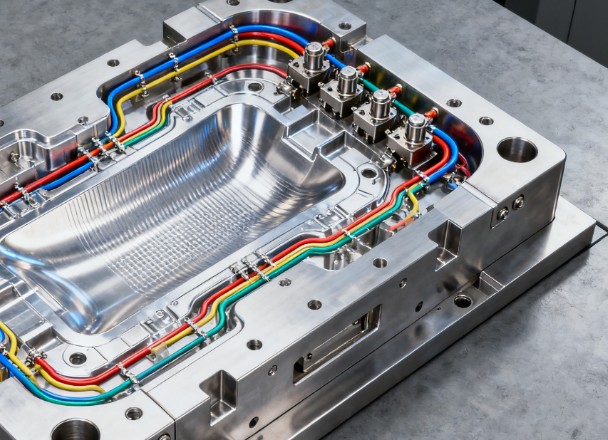

2.1 Cavity Design

Cavity design requires precise 3D modeling (using software like UG or SolidWorks) based on product shape and size. For 500ml PET preforms, cavity surfaces undergo mirror polishing to achieve Ra 0.2-0.4 μm, minimizing surface defects. Accounting for PET’s linear shrinkage (0.7-1.2%) and anisotropic characteristics, directional compensation is applied to cavity dimensions.

2.2 Gating System Design

Due to PET melt’s high viscosity and shear rate sensitivity, hot runner systems are typically used. Nozzles are made of titanium-plated 316 stainless steel (3-5 mm for <10g products; 5-8 mm for 10-50g products) to prevent adhesion of degraded PET. Smooth runners reduce pressure loss and ensure filling efficiency.

2.3 Cooling System Design

Proper cooling shortens cycle times by 15-20%. Water channels (spaced 20-30 mm, 15-20 mm from the cavity surface) use deionized water (20-30°C, 1-2 m/s flow rate) for uniform cooling. For slender products like preforms, internal core circulation cooling controls core temperature precisely.

3. Manufacturing and Maintenance of PET Injection Molds

3.1 Mold Materials and Processing

Cavities/cores use high-quality steel: S136 (HRC 52-56, for high transparency) or 718H (HRC 32-36, for mass production). High-speed milling (15,000-20,000 rpm spindle speed) ensures surface quality, while EDM (0.02-0.05 mm gap) shapes complex patterns. Final assembly requires template parallelism ≤ 0.01 mm/m and guide pillar/bushing clearance ≤ 0.005 mm.

3.2 Mold Maintenance

To meet FDA standards, post-production cleaning uses 40-50°C neutral detergent for hot runners; weekly lubrication with food-grade oil and monthly roughness checks (repolishing if Ra > 0.6 μm) are mandatory. Proper maintenance extends mold life from 500,000 to over 800,000 cycles, with maintenance costs at 1/20 of replacement costs.

4. Application Cases and Food Safety Requirements

4.1 Typical Case

A leading beverage company optimized a 128-cavity preform mold (Husky hot runner, ±1°C temperature control), reducing cycle time from 12s to 9.5s (20% output increase). Improved cooling cut wall thickness variation from 0.12mm to 0.06mm, lowering blow-molding defect rates from 3% to 0.8%. TPM management extended mean time between failures from 30 to 65 days, cutting annual maintenance costs by ¥400,000.

4.2 Food Safety Compliance

Molds must meet FDA 21 CFR Part 177.1310, with heavy metals (Pb/Cd ≤ 10 mg/kg) and VOCs absent from surfaces. Dead corners are avoided; runners use R ≥ 3mm arcs for easy cleaning. Melt contact surfaces are kept below 270°C to prevent acetaldehyde formation (≤ 1 ppm).

5. Conclusion

PET injection molds are critical to food packaging. Precision design, high-standard manufacturing, and strict maintenance enable high-quality, efficient production. As the industry demands lighter weight, better barrier properties, and higher recyclability, PET molds are advancing toward precision (±0.005 mm tolerance) and intelligence (integrated monitoring), supporting sustainable development.