Wear Resistance Sample Test Molds, Fatigue Sample Test Molds, Hardness Sample Test Molds

Sample test molds are core equipment in material performance testing systems, directly determining the accuracy and reliability of key indicators like wear resistance, fatigue resistance, and hardness. In automotive manufacturing, aerospace, mechanical equipment, and electronic information industries, they play a pivotal role in material selection, process optimization, and product quality control. By simulating real working conditions, these three specialized molds provide irreplaceable technical support for production decisions, with their design rationality, manufacturing precision, and technical adaptability directly influencing end-product safety and market competitiveness.

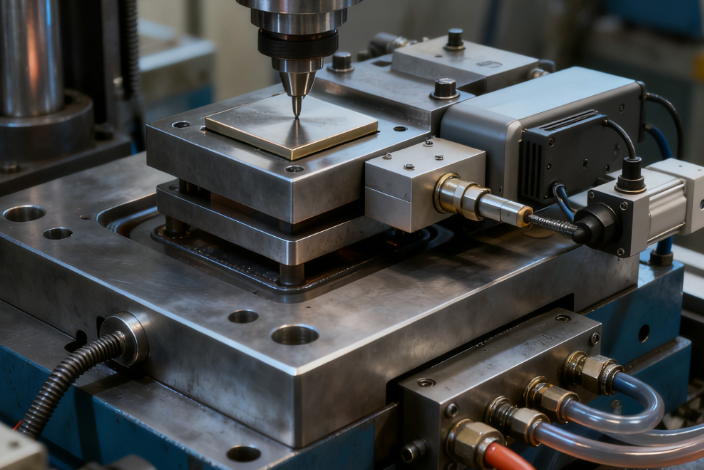

I. Wear Resistance Sample Test Molds

Design PrincipleThe core principle is simulating materials’ practical frictional environments, applying controllable pressure (0.5-5MPa), temperature, and relative motion (0.1-2m/s) to measure wear loss and friction coefficient. It reproduces dry friction, oil lubrication, or dust conditions to reflect material wear limits, supporting material selection for high-wear components.

Structural FeaturesAdopting a modular design, it includes upper/lower die bases, detachable friction pairs, positioning mechanisms, and heating/cooling systems. Guide pillars ensure ±0.005mm positioning accuracy; the heating/cooling system controls temperature from room temperature to 300℃ (±2℃); a wear collection interface links with laser thickness gauges for real-time data.

Material SelectionMold bodies use Cr12MoV alloy steel or SKD11 tool steel, reaching HRC58-62 after quenching and tempering. Friction pairs adopt cemented carbide (WC-Co) or silicon nitride ceramics (≥HRC65), with 3-5 times higher wear resistance than ordinary steel.

Technical TrendsDeveloping toward automation and intelligence, servo-controlled molds achieve ±0.01MPa load/speed regulation. Machine vision modules identify wear areas, while lightweight designs (high-strength aluminum alloy/carbon fiber) reduce weight by 20-30% for lab-production line switching.

II. Fatigue Sample Test Molds

Working MechanismApplies periodic tensile/compressive/bending/torsional loads (10-50Hz, 100-800MPa) for over 10^7 cycles to simulate alternating stress failure, measuring fatigue strength and life. Fatigue curves guide life prediction for springs, drive shafts, and wing components.

Key ComponentsCore parts include servo motor-driven ball screw loading devices (≤0.5% force error), high-precision strain gauge sensors (0-100kN, <5ms response), linear bearing guide mechanisms (±0.01mm repeat accuracy), and integrated control systems for automatic data recording and shutdown on fracture.

Precision AssuranceSymmetrical design ensures uniform loading; key surfaces are ground to Ra≤0.8μm. Load compensation offsets mold weight/friction errors, with calibration every ≤6 months to maintain data consistency.

Technological InnovationsIoT enables remote data transmission and cloud storage; intelligent monitoring warns of load/temperature anomalies. Ultrasonic flaw detection captures early cracks, and modular loading heads switch test modes (tension/compression/bending) for versatility.

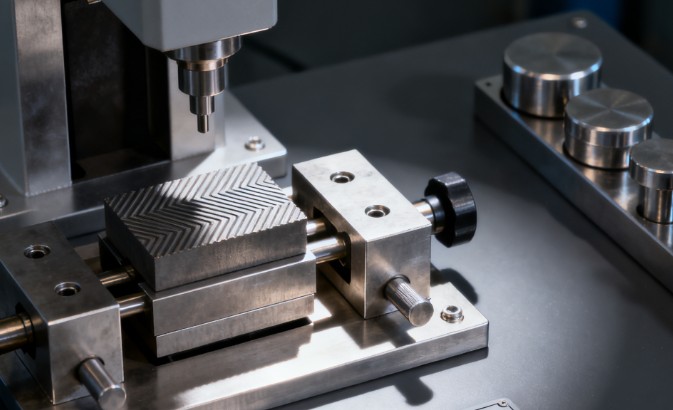

III. Hardness Sample Test Molds

Testing PrincipleBased on the indentation method, it applies specified pressure (60-150kgf for Rockwell, 3000kgf for Brinell, 1-120kgf for Vickers) with 10-30s indenter dwell time, evaluating hardness via indentation depth/diameter.

Mold Types

Rockwell: Diamond cone (120°) or 1.588mm carbide ball, suitable for high-strength materials.

Brinell: 10mm carbide ball, ideal for soft materials like non-ferrous metals.

Vickers: 136° square pyramid diamond indenter, for thin sheets/precision parts (±0.5HV accuracy).

Precision ControlIndenter dimensional accuracy is ±0.002mm (apex angle error ≤±0.5°). Loading systems have ≤±1% force error; worktable flatness ≤0.003mm/m. Temperature compensation corrects deviations at 15-25℃.

Technical BreakthroughsNano-coated indenters (HV20000+) extend service life by 30%. Integrated designs reduce repeatability error to ±0.3HV; automated molds boost efficiency by over 50%. Miniaturized models test <5mm micro-samples for electronics/precision machinery.

IV. Practical Applications and Case Studies

Industry Applications

Automotive: Tests piston rings (wear), springs (fatigue), and gears (hardness).

Aerospace: Verifies titanium alloy/composite performance for wings and engine blades.

Electronics: Miniature hardness molds test chip packaging; wear molds validate phone casings.

Case Studies

An auto parts firm optimized valve springs via fatigue testing, extending life by 50% and reducing after-sales failures.

A machinery manufacturer used hardness molds for 100% gear inspection, cutting non-conformity from 3% to <0.5%.

A new material company reduced polymer wear by 40% via mold testing, replacing steel for mine liners.

V. Conclusion

Technical SummaryWear molds focus on friction simulation and wear data collection; fatigue molds prioritize load stability and cycle accuracy; hardness molds rely on indenter/loading precision. All use high-strength materials and modular designs for industrial adaptability.

Future TrendsAI integration enables autonomous test optimization; green design reduces energy consumption; multi-functional molds realize combined testing (wear-fatigue, hardness-wear). Specialized molds for micro-nano/biological materials will support emerging fields, driving high-quality industrial production.