Unlocking Material Testing Codes: A Comprehensive Analysis of ISO, GB, and ASTM Standard Test Specimen Molds

Test specimen molds are core tools for material performance testing, whose design and manufacturing precision directly determine the accuracy, repeatability, and comparability of test data. In the global manufacturing and quality control system, ISO, GB, and ASTM standard molds dominate, catering to international general, domestic mandatory, and North American mainstream market needs respectively. This article focuses on their core characteristics to provide practical references for material R&D, production inspection, and quality certification.

Material performance testing is indispensable throughout industrial production. As key equipment for standard specimen molding, these molds must strictly comply with corresponding standards. ISO, GB, and ASTM systems have formed differentiated requirements based on regional industrial characteristics, with their molds sharing basic attributes like structural stability while boasting targeted design advantages.

I. ISO Standard Test Specimen Molds

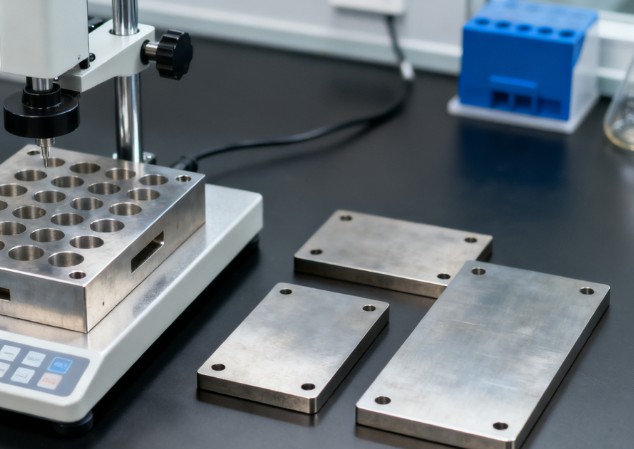

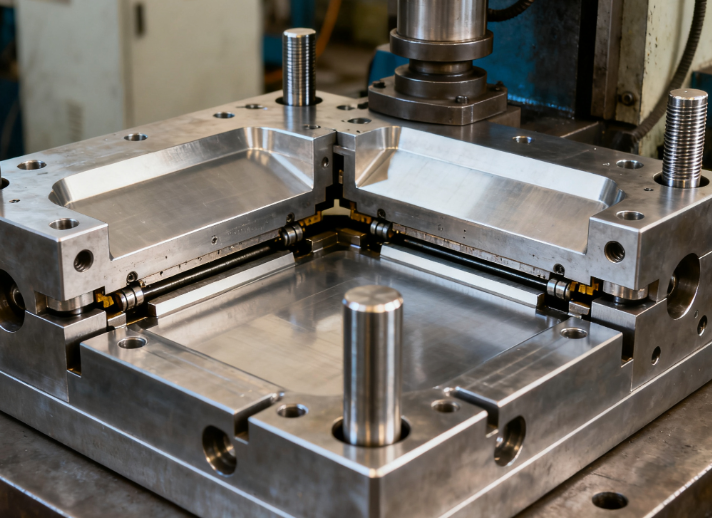

Design Key Points: Adhere to "versatility and compatibility", with cavity structures strictly following ISO standards. Modular design allows mold bases and cavity inserts to be disassembled and combined, adapting to plastics, rubber, metals, and composites. High-gloss cavity surfaces and optimized gates/runners reduce defects and stress concentration, while high-strength alloy steel mold bases ensure long-term stability.

Technical Parameters: Cavity dimensional tolerance ±0.02mm (ISO 8015); surface roughness Ra≤0.8μm (up to 0.4μm for high-precision); clamping gap ≤0.03mm; working temperature -40℃~250℃; guiding repeat positioning accuracy ≤0.01mm.

Application Scenarios: Widely used in multinational enterprises, export-oriented manufacturers, and international certification institutions. Suitable for preparing ISO 527 (tensile), ISO 179 (impact), and ISO 37 (rubber tensile) specimens, with internationally recognized test data supporting global market access.

Technical Trends: Digitization via CAD/CAE simulation and 3D printing (shortening development cycles by 30%+); integrated mold temperature monitoring for closed-loop control; environmentally friendly high-strength alloys balancing durability and low carbon emissions.

II. GB Standard Test Specimen Molds

Design Features: Balance "compliance and practicality", optimized for domestic materials like construction steel and engineering plastics. Standardized mold bases are compatible with domestic presses and injection machines, reducing adaptation costs. Quick mold change structures meet mass production needs of multi-specification specimens.

Performance Indicators: Key dimensional tolerance ±0.03mm (GB/T 1804-2000 m-level); service life ≥100,000 cycles; cavity wear ≤0.01mm/10,000 cycles; working pressure 10MPa~200MPa; stable operation at -10℃~40℃ (RH≤85%); demolding success rate ≥99.5%.

Application Scenarios: Dominates domestic manufacturing and engineering. Used for GB/T 228 (metal tensile), GB/T 1040 (plastic tensile), and GB/T 528 (rubber tensile) tests, widely applied in auto parts, construction steel, and rubber product quality control.

Technical Trends: Intelligence with sensors for real-time data collection and industrial Internet connection; greenization via energy-saving coatings and recycled materials; gradual alignment with international standards to enhance data mutual recognition.

III. ASTM Standard Test Specimen Molds

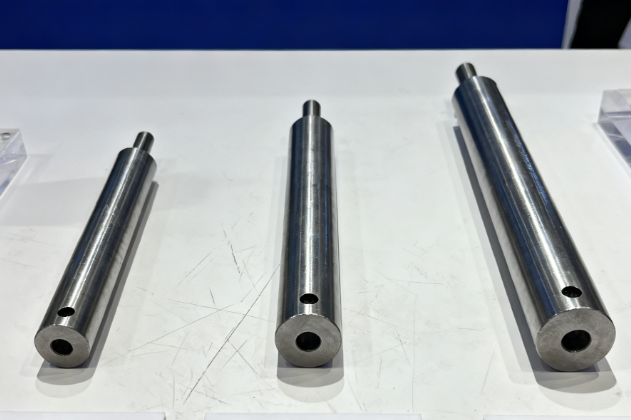

Structure & Design: Focus on "precision and specialization", with 3D-optimized cavities (e.g., ASTM D638 dumbbell shape) to reduce stress concentration. Shrink-fit process for mold bases and cavities ensures structural stability and avoids dimensional drift.

Key Specifications: Cavity dimensional tolerance ±0.025mm (ASTM E29); surface roughness Ra≤0.6μm; mold temperature control accuracy ±2℃; clamping force 50kN~500kN; weight error ≤1%.

Application Scenarios: Widely used in aerospace, medical devices, and high-end manufacturing. Adapt to ASTM E8 (metal tensile), ASTM D3039 (composite shear), and ASTM F648 (medical plastic) tests, meeting refined performance testing needs.

Technical Trends: Nano-coatings (TiN/DLC) doubling surface hardness; digital twin technology for full-life cycle simulation; customized molds for new energy materials; integration with automated testing equipment for efficient workflow.

IV. Comparison and Selection

Comparative Analysis: ISO (strong versatility, international recognition); GB (cost-effective, domestic equipment compatibility); ASTM (high precision, suitable for high-end R&D and North America). Core dimensional accuracy is comparable, with ASTM stricter in temperature control and GB superior in environmental adaptability.

Selection Guidelines: Prioritize GB for domestic market and supply chain; ISO for global export and international certification; ASTM for North American market or high-end material R&D. Consider material type, molding process, and test items for targeted selection.

V. Conclusion

ISO, GB, and ASTM standard molds each have distinct advantages, jointly supporting global manufacturing quality control. With the industry trending toward high-endization, intelligence, and greenization, these molds continue to evolve via digitalization and new material application. Enterprises should select molds based on market positioning and actual needs, ensuring compliant and advanced testing work. As global standards integrate, future molds will develop toward higher precision and stronger adaptability, empowering new material R&D and high-quality production.