Key Processing Points for Injection Molding of Electronic Device Enclosures

Injection molding is a core process for manufacturing electronic device enclosures, directly influencing product quality, production efficiency, and costs. As devices trend toward miniaturization and thinness, enclosures demand higher precision, structural complexity, and better appearance. Below are the key processing points organized by core links:

1. Material Selection

Mechanical Properties: Balance strength and toughness. For example, ABS is used for computer cases (high mechanical strength), PC for laptop enclosures (excellent toughness), and POM for high-friction parts like mouse/keyboard shells (good wear resistance).

Thermal Properties: Prioritize materials with good thermal stability (e.g., PC, with a heat distortion temperature of ~120°C for power adapter enclosures; PEEK for high-end heat-resistant components). Match the thermal expansion coefficient with internal parts to avoid fitting issues.

Electrical Properties: Choose PE/PS for insulation needs (common in wire/cable insulation); use ABS/PC with metal fibers or shielding alloys for electromagnetic shielding (e.g., mobile phones, computers).

Chemical Properties: Select nylon for corrosion resistance (for chemical-exposed scenarios); add antioxidants/light stabilizers to PC/ABS for outdoor use (enhance weather resistance).

Appearance & Processability: Use ABS/PC for high-gloss surfaces, ABS/PP for dyeability (via color masterbatches). PP suits complex thin-walled parts (good fluidity); PC requires high injection pressure. Control shrinkage (e.g., special processes for POM to prevent deformation).

Cost: Opt for low-cost general plastics (PP, PE) when possible; use engineering plastics (PC, PA) for high-performance needs. Consider processing costs and recyclability to reduce losses.

2. Mold Design

Structural Design: Determine parting surfaces based on enclosure details (keyholes, interface slots) for smooth demolding. Design cooling channels close to the cavity (ensure uniform cooling to prevent deformation) and match mold surface treatment to special appearances (mirror/matte).

Material Selection: Use P20 steel for general molds (easy processing, good polishing); H13 steel for high-precision/high-output molds (maintains hardness and toughness at high temperatures).

Maintenance: Regularly clean cavity residues (prevent appearance/size deviations) and cooling channels (avoid blockages). Inspect moving parts (sliders, ejector pins) to prevent demolding failures.

3. Injection Process Parameter Control

Temperature Control: Set barrel temperature by material (180–220°C for PP); keep nozzle temperature slightly lower than the maximum barrel temperature (prevent premature solidification). Use 80–100°C mold temperature for high-gloss enclosures.

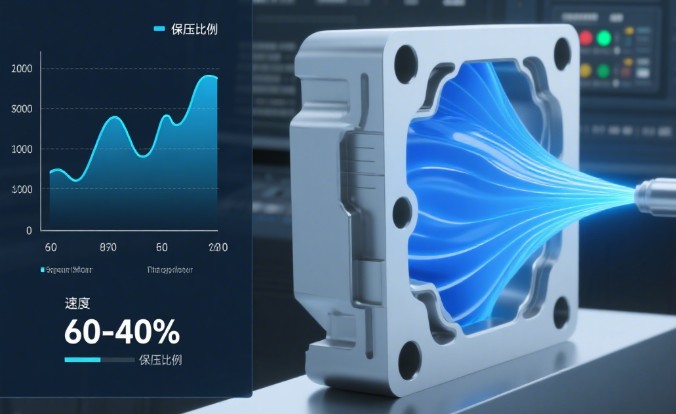

Pressure & Speed Control: Adjust injection pressure to avoid flash (excessive pressure) or short shots (insufficient pressure). Match injection speed to the product—too fast causes jetting, too slow reduces efficiency (test based on material and shape).

Hold Pressure & Cooling Time: Set hold pressure to 60–80% of injection pressure (prevent shrinkage, depression ≤0.1mm) and adjust time by product size. Ensure sufficient cooling time (avoid deformation from insufficient cooling or inefficiency from excessive cooling).

4. Injection Process Monitoring

Real-Time Parameter Monitoring: Track pressure, temperature, and speed via sensors. Stop the machine for abnormalities (e.g., sudden pressure spikes may indicate cavity debris).

Filling Observation: Use transparent molds or visual equipment to check melt flow. Adjust parameters or inspect gates if short shots occur.

5. Quality Control

Appearance Inspection: Check for shrinkage, flash, bubbles, and weld lines. Ensure uniform color and no foggy areas on high-gloss surfaces.

Dimensional Control: Measure key dimensions (e.g., keyholes) with calipers/micrometers (tolerance ±0.1mm). Sample and adjust molds/processes if deviations occur.

Performance Testing: Conduct mechanical tests (tensile/impact strength, e.g., drop resistance for tablets), electrical tests (insulation resistance, EMC), and environmental tests (temperature resistance, weather resistance, flame retardancy—meet UL94 standards).

6. Conclusion

Injection molding of electronic enclosures requires synergy between materials, molds, processes, monitoring, and quality control. Deviations in any link may cause defects. Optimize solutions based on device needs and adopt new technologies to improve precision and efficiency, ultimately balancing product performance and market competitiveness.