Key Processing Points for Injection Molding of Medical Equipment

1. Material Selection

Materials for medical equipment injection molding must first meet biocompatibility requirements (in line with ISO 10993) to avoid toxicity or allergies when in contact with the human body, while also balancing mechanical properties like strength and toughness, and resistance to chemicals and high temperatures. Common options include PEEK—ideal for orthopedic implants due to its high strength and long-term stability—PP, which is cost-effective and easy to process for disposable items like syringes, and PC/PU, where PC is used for transparent housings (e.g., glucose meters) and PU for flexible parts like catheters. Suppliers need to provide qualification certificates and test reports, and each batch of materials must undergo sampling inspections to check component stability (such as polymer molecular weight fluctuation ≤5%) and impurity content (metal particles <10μm).

2. Production Environment

The injection molding process for medical devices requires strict environmental control. Regular consumables (e.g., syringes) need an ISO 8 (Class 100,000) cleanroom, with no more than 352,000 particles (≥0.5μm) per cubic meter, while high-precision parts like implants demand an ISO 7 (Class 10,000) or higher standard, supported by HEPA filters to prevent microbial and dust contamination. Temperature must be stabilized at 18–26°C and humidity at 45%–65% to avoid material moisture absorption (e.g., PP becoming sticky at humidity >65%) and ensure process stability. Staff must wear anti-static dustproof suits, N95 masks, and nitrile gloves, and pass through air shower purification for over 30 seconds, with restricted operations to avoid human-related contamination.

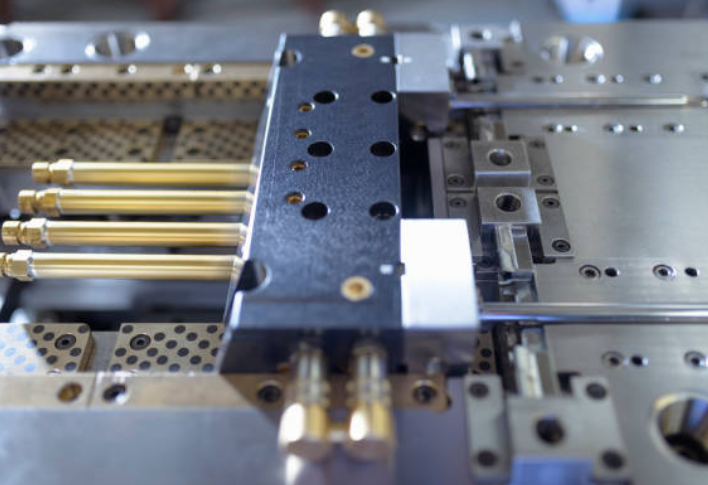

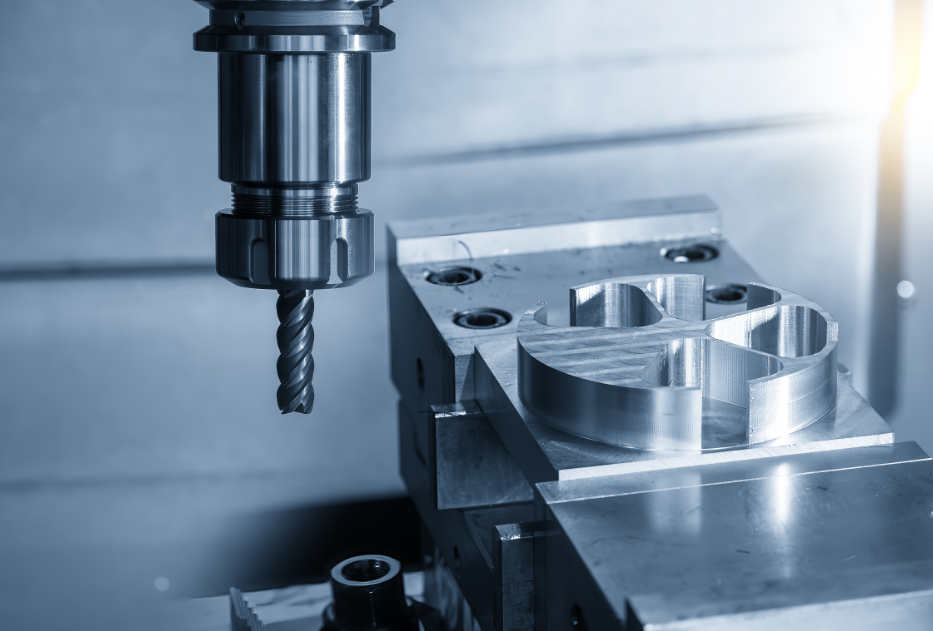

3. Mold Design & Manufacturing

Mold design starts with optimizing runners using CAE software (e.g., Moldflow) to ensure uniform melt flow and prevent pressure concentration (pressure difference <5MPa for complex cavities). For undercut structures like catheter threads, sliders or angled ejectors are used, and thin-walled parts (<0.5mm) require a draft angle of 3°–5° to avoid warpage (controlled within 0.2mm). Mold materials include S136 stainless steel (for high-transparency, precision products) and SKD61—after nitriding (hardness HRC 50–55), it is suitable for wear-resistant scenarios like multi-cavity syringe molds, extending service life to over 500,000 cycles. Processing relies on ultra-precision 5-axis machines (positioning accuracy ±0.001mm) to control mold tolerances (±0.003mm for implants), with coordinate measuring machines (accuracy ±0.002mm) and CT scanning used to inspect cavity size and surface roughness (≤Ra 0.2μm).

4. Injection Process Control

Key injection parameters are tailored to part characteristics: thin-walled parts (e.g., heart stents, 0.1–0.3mm thick) use 60–80MPa pressure and 30–50mm/s speed to shorten filling time (with barrel residence ≤2min to reduce degradation), while thick-walled parts (>3mm, e.g., implant housings) require 100–120MPa pressure and 10–20mm/s speed to lower shrinkage (≤1%). Holding time ranges from 5–8s (thin parts) to 12–15s (thick parts), and cooling time is 15–30s, with mold temperature adjusted (e.g., 80–100°C for PC) to ensure dimensional tolerance ≤±0.05mm. Closed-loop systems monitor pressure (fluctuation ≤±2MPa) and melt temperature (deviation ≤±3°C) to adjust screw speed automatically, and MES databases store optimal parameters verified by DOE for mass production.

5. Quality Inspection

Basic inspections include dimensional checks using coordinate measuring machines (with laser scanners) for key sizes (e.g., syringe inner diameter tolerance ±0.02mm), supported by SPC (Cpk ≥1.33) to monitor fluctuations, and visual inspections via CCD systems (≥2MP resolution) to detect defects like bubbles (>0.1mm) or flash (>0.05mm), with AI boosting accuracy to over 99%. Medical-specific tests cover biocompatibility (per ISO 10993: cytotoxicity with cell viability ≥70%, sensitization ≤10% in guinea pigs, negative Ames test) and mechanical properties (e.g., PP tensile strength ≥30MPa, catheters withstanding 10,000 bends). All records (raw material batches, parameters, test data) are stored electronically and in paper form for ≥5 years, with ERP-linked unique codes enabling full traceability.

6. Post-Processing

Deburring uses CNC milling (allowance ≤0.03mm) for rigid materials like PC, and cryogenic methods (-100°C to -150°C with 0.2–0.5mm nylon shots) for complex parts, improving efficiency by 3–5x. Cleaning involves 5–10 minutes of ultrasonic cleaning (40kHz, 500W) with medical detergents, followed by rinsing with purified water (conductivity ≤1μS/cm) and drying at 60°C for 15 minutes (particle count ≤10/mL for particles >5μm). Sterilization options include ethylene oxide (50–60°C, 600–800mg/L, 4–6h, residue ≤10μg/g after 72h aeration) for heat-sensitive parts, irradiation (Co-60, 25–50kGy) for disposables, and autoclaving (121°C, 103kPa, 15–30min) for heat-resistant parts, ensuring a sterility assurance level (SAL) ≤10??.

7. Documentation & Management

Records cover raw material files, mold designs, process data, quality reports, and equipment maintenance logs, managed in compliance with ISO 13485—electronic records are stored on encrypted servers, and paper records in fireproof archives, with revisions requiring approval (e.g., by technical managers) and version tracking. This documentation enables rapid tracing of quality issues (e.g., material batches or mold wear) and ensures compliance with FDA and EU MDR requirements, enhancing market competitiveness.