Mold Design and Injection Process Optimization for Custom Plastic Parts

Introduction: The Core Role of Mold and Injection Process

In custom plastic part production, mold design and injection molding processes are critical to product quality, efficiency, and cost control. As plastic products find wider applications, demands for precision, performance, and shorter lead times have grown, making optimization of these two areas essential for enterprise competitiveness.

Key Considerations in Mold Design

Effective mold design starts with aligning with product requirements. This includes accounting for material shrinkage—1.5%-3.5% for polyethylene (PE) and 0.5%-0.7% for polycarbonate (PC)—to adjust mold dimensions. Uniform wall thickness is key; thick sections should use ribs no more than 70% of the wall thickness to avoid defects like sink marks. Draft angles of 0.5°-3°, fillet transitions (R0.5+), and strategic parting surfaces (at the product’s minimum contour) further enhance mold performance.

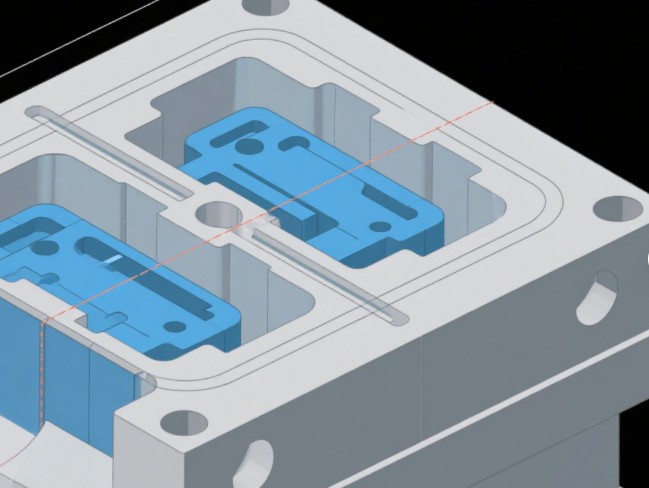

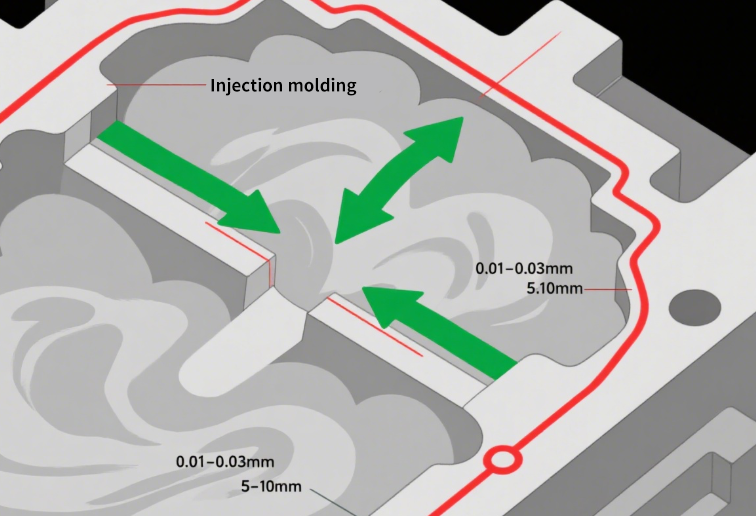

For structure, multi-cavity molds require symmetric cavity layouts, while inserts simplify maintenance for complex parts. Gating systems need properly sized sprues/runners and well-placed gates to prevent weld lines, plus cold slug wells to trap cold material. Cooling systems use channels near the cavity (8-12mm diameter) to reduce cycle times—e.g., 15-25 seconds for 3mm thick polypropylene (PP) parts—while ejection systems rely on evenly spaced, durable ejector pins to avoid deformation. Vent grooves (0.01-0.03mm deep) at filling endpoints ensure proper air release.

Precision Control in Injection Process Optimization

Injection process optimization depends on precise parameter control. Temperature settings vary by material: for ABS, barrel temperatures range 180-240℃ (rear to front) with a 210-230℃ nozzle. Injection pressure and speed are tailored to product size—80-100mm/s for 1mm thin-walled parts and 100-150MPa for large automotive components.

Holding pressure (60%-80% of injection pressure) and time (10-30 seconds) prevent shrinkage, while cooling times (20-60 seconds total) ensure solidification—e.g., 15 seconds holding and 30 seconds cooling for 4mm polyoxymethylene (POM) parts.

Advanced methods like the Gaussian-model-based Estimation of Distribution Algorithm (EDA) have proven effective, cutting defect rates from 5%-8% to 2%-3% and reducing energy use by 15%-20% in real-world applications.

Conclusion: Synergy and Future Trends

Mold design and injection processes are inherently interconnected: good mold design provides a foundation for process efficiency, while precise process control maximizes mold potential. By integrating these elements, enterprises can boost quality, cut costs, and shorten lead times. Future advancements in 3D printing, smart injection systems, and new materials will continue to drive innovations in custom plastic part manufacturing.