Key Processing Points for Automotive Component Injection Molding

In modern automotive manufacturing, injection molding is widely used to produce various auto parts—from large bumpers

and instrument panels to small interior trim pieces and electronic component housings. The strict automotive industry

requirements for part quality, safety, and durability demand precise control over every link in automotive component injection

molding. This article details the key processing points of the process.

1. Material Selection and Preprocessing

1.1 Material Selection

Automotive parts serve in complex environments, requiring high-performance materials. For example:

Bumpers, needing high impact resistance, often use modified polypropylene (PP) blended with elastomers (e.g., EPDM) to

enhance energy absorption.

Engine compartment parts, enduring high temperatures, adopt heat-resistant ABS modified with 3%-5% nano-SiO?, which

raises the heat distortion temperature to 150℃ (meeting the >110℃ engine compartment environment).

Interior parts, prioritizing low odor and low volatility, use materials added with 5% zeolite or porous molecular sieves to reduce

aldehyde/ketone emissions.

Common materials also include polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), and polyamide (PA)—selected based

on the part’s specific function and application environment.

1.2 Material Preprocessing

Moisture and impurities in materials cause injection defects:

Hygroscopic materials (e.g., PC/ABS alloys) must be dried with dehumidifying dryers to control moisture content below 0.2%.

Low-hygroscopic modified PP only needs 80-100℃ hot air drying for 2-3 hours.

Recycled PC/ABS requires 6 hours of drying at 100-120℃ plus epoxy chain extenders to repair molecular chain breakage, ensuring

impact strength ≥18kJ/m2 and compliance with VDA270 odor standard (Grade ≤3).

Adding 20%-30% talc reduces VOC emissions by over 40% by inhibiting small-molecule volatilization.

2. Mold Design and Manufacturing

2.1 Mold Design

Gate Design: Large parts (e.g., bumpers) use hot runner systems and multi-point gates for uniform melt filling (reducing flow marks).

Gate size is calculated based on part size, wall thickness, and material properties.

Ventilation System: Vents (0.05-0.1mm wide, 0.02-0.03mm deep) are placed at mold parting lines or deep cavities to avoid bubbles/

silver streaks. Porous steel can also improve ventilation.

Cooling System: Coolant channels are arranged by part shape and wall thickness to ensure uniform cooling—temperature difference

between fixed and moving molds is controlled within 2℃ to prevent thermal deformation.

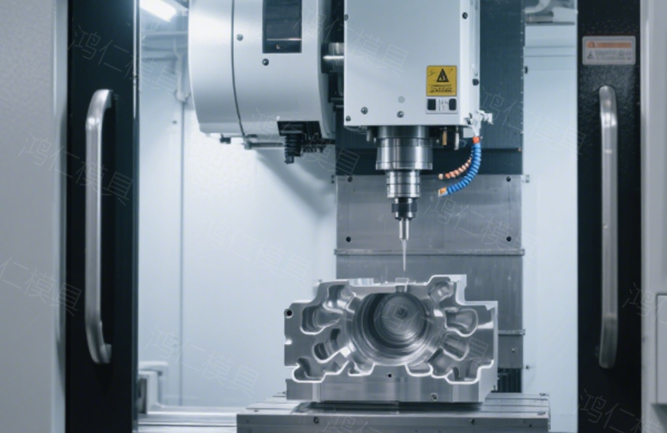

2.2 Mold Manufacturing

Mold precision determines part dimensional accuracy:

High-quality mold steels (e.g., P20, 718, H13) are heat-treated to HRC48-52, suitable for 1-million-piece mass production (wear-resistant

for glass fiber-reinforced materials).

Aluminum molds (used for small-batch high-precision parts like grilles) shorten cooling cycles via good thermal conductivity but are

limited in mass production due to low hardness.

Key dimensional tolerance is controlled within ±0.05mm, with strict surface finish requirements.

3. Injection Process Parameter Control

3.1 Temperature Control

Barrel Temperature: Set by material—e.g., 180-220℃ for PP. Excess temperature causes material degradation; insufficient temperature

leads to poor melt flow (short shots, cold marks).

Mold Temperature: Critical for melt flow and cooling rate—e.g., 80-120℃ for PC molding, adjusted by material and part type.

3.2 Pressure and Time Control

Injection Pressure: Adjusted by part shape, mold structure, and material flowability. Complex parts need higher pressure (avoiding

flash/die damage), with average cavity pressure 25-40MPa.

Hold Pressure & Time: Compensates for melt shrinkage (preventing sink marks/voids). Pressure is balanced to avoid internal stress;

time is determined via experiments/simulation based on part thickness.

Injection Time: Optimized with injection speed—too short causes short shots; too long increases energy consumption.

3.3 Other Parameter Control

Screw Back Pressure: Moderate pressure improves melt uniformity/density; excess pressure causes degradation and higher energy

use (adjusted by plastic type and part structure).

Injection Speed: Multi-stage control—low speed initially to avoid turbulence, then increased for fast, uniform filling (reducing internal

stress and surface defects).

4. Quality Inspection and Problem Solving

4.1 Common Quality Issues

Surface Defects: Flow marks (uneven melt flow), weld lines (melt convergence), silver streaks (moisture/volatiles), bubbles (trapped

air/gas).

Dimensional Deviations: Caused by poor mold precision, process fluctuations, or material shrinkage differences (affecting assembly).

Mechanical Performance Failures: Insufficient strength/toughness from wrong material selection, injection defects (bubbles/voids),

or poor structural design.

4.2 Quality Inspection Methods

Visual Inspection: Check surface defects and color consistency (with magnifiers if needed).

Dimensional Inspection: Measure key dimensions with calipers, micrometers, or CMMs (comparing to design standards).

Performance Testing: Conduct tensile, bending, and impact tests; add functional tests (e.g., air tightness) for specific parts.

4.3 Problem-Solving Measures

Mold Optimization: Improve gate design, enhance ventilation, or repair worn/deformed mold parts.

Process Adjustment: Precisely control temperature/pressure/time; optimize material drying and mixing.

Material Replacement/Processing: Use stable-quality materials; properly treat recycled materials to meet performance requirements.

5. Conclusion

Automotive component injection molding is a systematic process involving materials, molds, processes, and quality inspection. Only

by strictly controlling each key point and continuously optimizing can high-quality, high-performance parts be produced to meet strict

automotive standards. As the automotive industry evolves, injection molding technology demands further innovation to keep pace

with market needs.