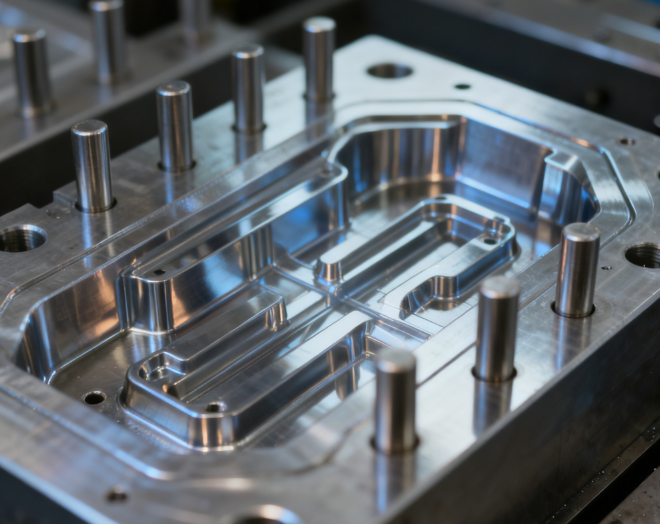

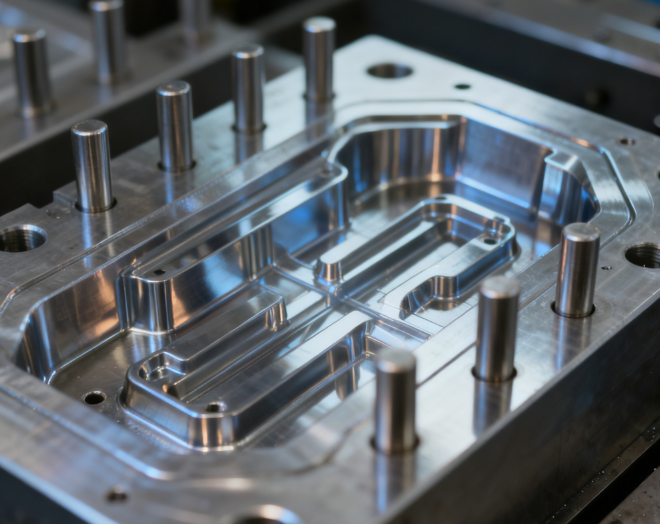

As a core pillar of modern manufacturing, plastic mold customization covers precision and non-standard segments. Its core value lies in tailored design and processing to meet personalized requirements for product structure, precision, and production capacity across industries. From auto parts and electronic enclosures to medical supplies, high-quality customization ensures molding efficiency and quality. Test bar molds, as critical verification tools, directly determine final mold adaptability and mass production stability, bridging design and production.

The primary step is demand concretization. Based on product drawings, material properties, production volume, and application scenarios, clarify three core parameters:

Product precision: Dimensional tolerance (±0.01mm~±0.05mm for precision, ±0.05mm~±0.2mm for standard), surface roughness (Ra≤0.8μm for high-gloss);

Material compatibility: Melt flow rate, shrinkage rate (0.5%~2.0%), and heat resistance for PP, PC, ABS, PA66+GF, etc.;

Production efficiency: Single-cavity cycle (15s~60s), daily output (5,000~50,000 units), mold service life (≥500,000 cycles for standard, ≥1,000,000 for precision).

Adaptability: Mold structure aligns with product design (optimized parting surfaces, guiding mechanisms for deep cavities);

Reliability: Critical components (core, cavity, ejector pins) use S136/H13 alloys (HRC50~HRC55 after heat treatment);

Economy: 1~2 cavities for small-batch non-standard customization, 4~8 cavities for large-batch precision production.

Targeting micron-level accuracy with industry-recognized indicators:

Dimensional precision: Cavity tolerance ±0.005mm~±0.01mm, repeat positioning accuracy ≤0.003mm;

Surface quality: Ra≤0.4μm, free of tool marks/sand holes;

Molding stability: Dimensional fluctuation ≤±0.008mm over 1,000 cycles, defect rate ≤0.3%.

Material: S136 steel (13%~14% chromium) for 30% higher wear resistance;

Processing: 5-axis CNC (±0.002mm) + EDM (Ra≤0.2μm) + WEDM;

Assembly: Laser interferometer for guide clearance (≤0.001mm), Moldflow simulation for gate/runner optimization.

Dimensional verification: ISO 527 tensile bars measured by CMM (deviation ≤±0.005mm);

Material compatibility: Testing flow adaptability of PC/ABS, PA66+30%GF;

Stability test: 500 consecutive cycles (dimensional variation ≤±0.003mm) for parameter validation.

For complex-structured, small-batch (≤100,000 units) products with no standard references:

Structural personalization: Adapting to irregular cavities, multi-slide core pulling, thread demolding;

Process flexibility: Cold/hot runner, water/oil cooling systems;

Cycle adaptability: Rapid test bar mold iteration for cost-efficient R&D.

Modular structure for easy maintenance;

FEA-optimized cavity thickness (≥8mm) and guide pillar diameter (≥20mm);

0.1~0.2mm wide, 0.01~0.02mm deep vents to eliminate bubbles.

Structural feasibility: Verifying mechanism coordination;

Parameter optimization: Adjusting injection pressure (80~150MPa), speed (50~200mm/s), cooling time (10~30s);

Material matching: Testing shrinkage/mechanical properties of PPS, PC;

Cost control: Ensuring defect rate ≤1%.

Digital design: 3D modeling + Moldflow (30% shorter R&D cycles);

Rapid tooling: 3D-printed test bar cavities (±0.01mm, 7~10-day R&D);

Green manufacturing: Eco-friendly alloys, water-saving cooling, waste heat recovery.

Three-round design review;

Standardized test reports (dimensional data, mechanical properties, parameters);

1-year warranty with 48-hour technical response.

Plastic mold customization delivers value through precise demand analysis, scientific design, and rigorous test bar validation. With digital and green technology advancements, the industry moves toward higher precision, efficiency, and sustainability, supporting personalized product R&D and mass production.