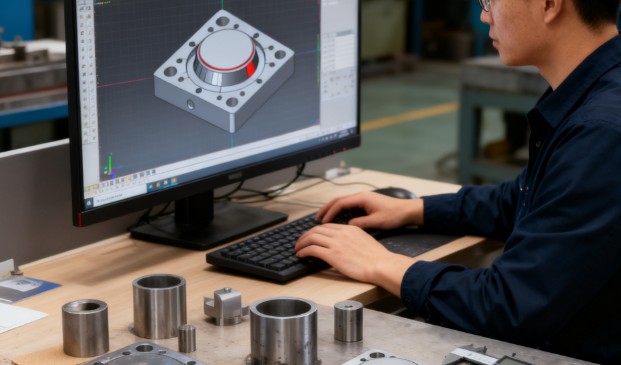

The material selection and heat treatment process of custom household appliance plastic molds directly determine molding precision, service life, and production stability. With the household appliance industry trending toward lightweight, precision, and intelligence, molds must adapt to various plastic materials such as ABS, PC, PP, and PA+glass fiber, while meeting requirements for wear resistance, deformation resistance, and machinability in mass production. Scientific selection and heat treatment plans should be formulated based on appliance type, plastic part function, and production scale.

Classification by Appliance Type and Part Function

Large household appliance molds (e.g., refrigerator side panels, air conditioner casings): Use pre-hardened steels like P20 and 718H (hardness HRC 28-35) for direct machining and polishing, eliminating the need for secondary heat treatment and shortening mold opening cycles.

Small household appliance molds (e.g., soybean milk machine cups, rice cooker lids): Adopt corrosion-resistant steels such as S136 and 2316 to suit thin-walled parts and prevent cavity corrosion during high-temperature injection molding.

Functional component molds (e.g., appliance gears, motor brackets): Select hot-work steels like H13 and SKD61 to withstand wear from reinforced materials such as PA+glass fiber, ensuring a service life of over 500,000 cycles.

Transparent plastic part molds (e.g., refrigerator drawers, air conditioner air deflectors): Use high-purity mold steel to achieve a mirror finish with surface roughness Ra ≤ 0.01μm.

Key Performance Requirements

High-temperature service parts (e.g., oven liners, water heater components): Mold materials must withstand temperatures around 600℃ with good thermal fatigue resistance.

High-volume production molds: Materials should balance hardness and toughness to avoid fracture during long-term mold opening/closing.

Export-oriented appliance molds: Use lead-free, low-sulfur environmentally friendly steel compliant with EU RoHS and China GB/T 26572 standards.

Ultra-thin plastic part molds (wall thickness ≤ 1.2mm): Adopt high-strength, high-toughness advanced steel with surface coating technology to reduce melt flow resistance.

Trends in Innovative Material Applications

Composite structure design: High-strength mold steel for cavities (ensuring precision) and aluminum alloy for mold bases (reducing weight by over 30%) to improve injection molding machine efficiency.

Cost-adaptive selection: For small-batch production (≤ 100,000 cycles), surface-hardened 45# steel can be used to reduce costs by 20%-30% while meeting basic precision requirements.

Corrosion resistance enhancement: For plastic parts with special additives, use more corrosion-resistant mold steel to prevent cavity oxidation and peeling.

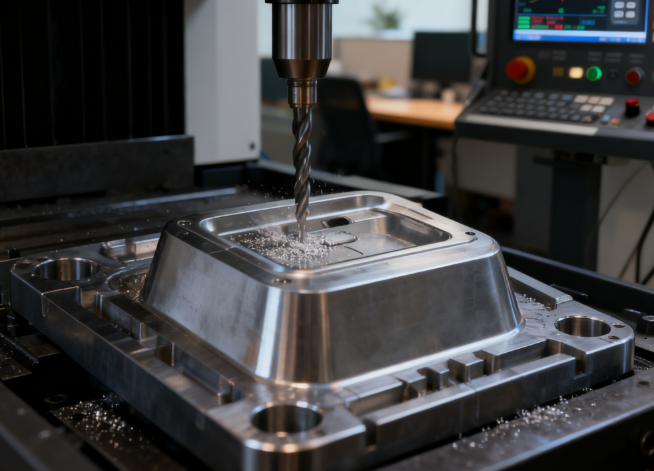

Pre-treatment Processes

Pre-hardened steels (P20, 718H): Annealing at 720-760℃ for 2-3 hours followed by furnace cooling to ensure uniform hardness and eliminate forging internal stress.

Non-pre-hardened steels (H13, S136): Normalizing at 850-900℃ for 1-2 hours followed by air cooling to reduce hardness and improve machinability.

High-carbon steel: Stress relief annealing at 650-700℃ for 3 hours to minimize deformation risk during subsequent heat treatment.

Final Heat Treatment Parameters

H13 steel (functional component molds): Quenching at 950-1050℃ followed by oil cooling, with three tempering cycles to achieve a final surface hardness of HRC 50-55.

S136 steel (transparent part molds): Quenching at 1020-1050℃ followed by cryogenic treatment at -80℃ to -120℃ for effective deformation control.

2316 steel (corrosion-resistant molds): Quenching at 980-1020℃ followed by two tempering cycles, controlling surface hardness at HRC 48-52 to enhance corrosion resistance.

Post-treatment and Quality Control

Wear resistance treatment: Gas nitriding of cavity surfaces at 500-550℃ for 4-6 hours, achieving a nitrided layer hardness of HV 800-1000 and extending mold life by 2-3 times.

Mirror finishing: Follow a "rough polishing - fine polishing - mirror polishing" process to meet high-gloss requirements for transparent parts.

Quality inspection: Focus on hardness uniformity, flatness error, and surface defects, with key dimensional accuracy controlled at the micrometer level to ensure no cracks or pitting.

Matching Mold Structure with Materials

Complex cavity molds (e.g., appliance control panels): Use 718H for excellent machinability, reducing cutting difficulty and tool wear.

Deep-cavity molds (e.g., washing machine inner tubs): Adopt tough H13 steel to prevent cavity chipping during demolding.

Multi-cavity molds (e.g., appliance button molds): Select S136 for uniform hardness to ensure consistent part dimensions across cavities.

Synergistic Optimization of Injection Molding Processes

High-speed injection (thin-walled parts): Mold materials require high rigidity to avoid deformation, reinforced by quenching and tempering.

High-temperature injection (PC, PA+glass fiber): Cryogenic treatment of molds to reduce dimensional deviation caused by thermal expansion.

Injection of glass fiber-reinforced plastics: Nitriding of mold cavities to enhance wear resistance against glass fiber erosion.

Mold Maintenance and Service Life Extension

Regular polishing: Restore worn cavity surfaces with professional polishing materials to prevent part scratching.

Rust prevention: Apply anti-rust oil to idle molds stored in dry environments.

Repair processes: Local cavity wear can be repaired by argon arc welding with matching material welding wire, followed by local heat treatment to ensure hardness consistency.

Custom household appliance plastic molds require adherence to the principles of "material adaptation to parts, heat treatment adaptation to materials, and process synergistic optimization." Scientific mold steel selection, standardized heat treatment, innovative material applications, and precise process control ensure molds offer excellent precision, wear resistance, and stability. This not only meets the demands of precision and mass production in the household appliance industry but also controls costs and shortens cycles, laying a solid foundation for improving product quality.