Application and Development of ABS Injection Molds for Auto Parts

I. Application Scenarios and Core Requirements

ABS and ABS alloy materials, with integrated rigidity, toughness and processability, have become key substrates for

auto parts. Their injection molds are applied in three major fields: interior, exterior and functional structural parts.

(I) Main Application Fields

Interior parts: Core components like instrument panel frames, door trim panels and central control panels rely on high-precision

ABS injection molds. These molds need high surface gloss and adapt to molding characteristics of modified materials such as

ABS/PMMA alloys.

Exterior parts: Molds for grilles, pillar trim panels, etc., must meet outdoor weather resistance requirements, usually using

corrosion-resistant mold steel and special surface treatment.

Functional structural parts: Molds for air conditioning housings, steering column covers, etc., need to solve technical problems

like multi-insert and complex core-pulling. For example, molds for glass fiber-reinforced ABS housings require synchronous and

precise multi-directional core-pulling.

(II) Core Requirement Features

The auto industry's core demands for ABS molds focus on three aspects:

Batch stability: Molds for mainstream models need long-term trouble-free production to meet mass production needs.

Environmental compliance: Interior parts molded must pass professional odor tests and meet auto interior environmental standards.

Cost control: Comprehensive manufacturing costs in the mold life cycle should be reduced while ensuring quality.

II. Key Technologies in Mold Design and Manufacturing

(I) Structural Design Optimization

Mold design has shifted from empirical to digital precision design, with core optimization directions including:

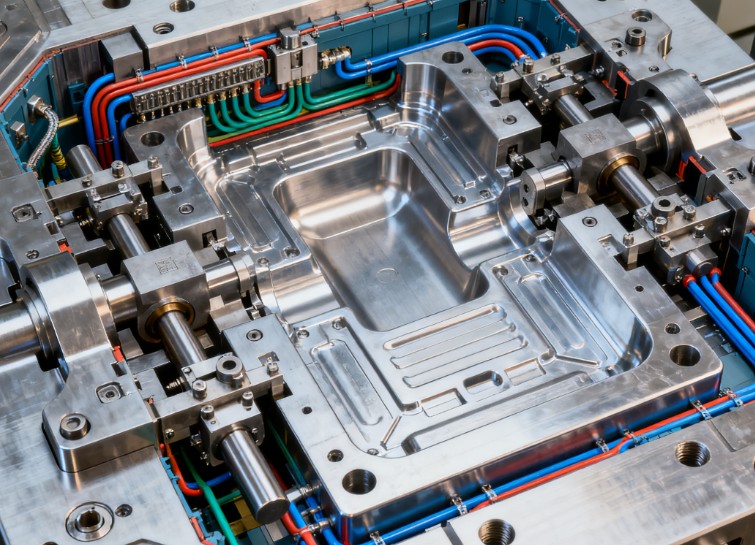

Multi-core-pulling structure: Linkage mechanisms (swing block-pin-disc spring) enable multi-directional core-pulling in small

spaces, improving molding success rate.

Gating system: Matching ABS properties, design sprue diameter and runner cross-section to reduce flow resistance; optimize gate

position via CAE simulation to avoid weld lines on appearance/force-bearing areas.

Cooling system: Conformal water channels and 3D-printed special-shaped cooling inserts precisely control cavity temperature

and shorten cooling time.

Venting system: Precision vent grooves at melt ends and deep ribs, plus porous steel inserts, solve gas trapping and burning.

(II) Material and Process Matching

Mold material selection: Pre-hardened steel for medium-batch production; quenched-tempered steel (excellent polishing) for

mass interior parts; carburized-quenched guide pillars/bushings for surface hardness and core toughness.

Molding process optimization: Standardized system including raw material pre-drying (to avoid hydrolysis odor), precise temperature

control (higher mold temperature for better interior surface quality), and multi-stage injection with reasonable holding pressure.

III. Typical Defect Control and Quality Improvement

A defect prevention system based on 5M1E analysis supports ABS mold production, with mature solutions for common defects:

Filling defects (short shot): Optimize venting (add vents at material-shortage areas) and adjust injection parameters (multi-stage

injection) to improve yield.

Weld lines: Increase mold temperature (improve melt fusion) and adjust gate position (optimize flow convergence angle) to restore

impact strength.

Surface sink marks: Control rib/main wall thickness ratio (design stage) and extend holding time (process stage) to enhance flatness.

Odor control: Adopt zoned temperature control and vacuum devolatilization to reduce VOC content of products.

IV. Technology Development Trends

Intelligence and greenization are core directions, showing three trends:

Digital and intelligent upgrading: CAE simulation predicts the whole process (design to parameters) to reduce test runs; mold

condition monitoring systems collect real-time data to extend predictive maintenance cycles.

Material and coating upgrading: Nano-modified ABS drives adoption of high-hardness powder metallurgy steel and DLC coating

(extend mold life); recycled ABS achieves high-quality molding via custom molds.

Integration of precision and environmental protection: With auto lightweighting and intelligence, ABS molds will develop towards

precision and integration, combining 4D deformation compensation and bio-based plasticizers for high performance and environmental

protection.