Microcellular Injection Molding Dies: Full Process from Design to Mass Production

Microcellular injection molding dies are core equipment for achieving polymer lightweighting and precision molding,

requiring a balance between melt flow and cell growth laws. Their design and control directly determine product performance.

This article outlines the complete technical process from design to mass production based on industry practices.

1. Core Die Design: Balancing Precision and Foaming Adaptability

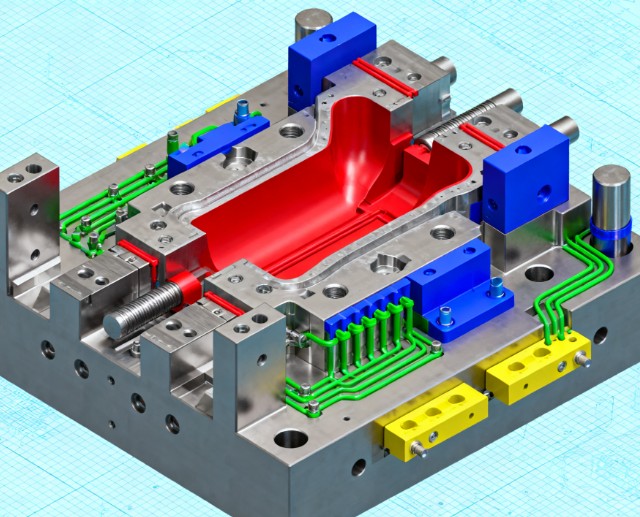

1.1 Cavity and Gating System

The cavity structure must match cell growth rules. For 3C precision parts, the cavity surface roughness must be strictly

controlled to avoid surface defects such as depressions and silver streaks caused by cell rupture.

The gating system preferably uses submarine gates, with diameters adapted to product weight, wall thickness, and material

fluidity—excessively thin gates for thin-walled small parts may cause foaming abnormalities, while overly thick gates for

thick-walled large parts may lead to melt retention. For optical materials like PC/PMMA, the sprue taper is set at approximately

3° to reduce uneven foaming caused by prolonged melt residence.

1.2 Functional System Design

The venting system adopts a multi-stage structure: the depth of the main vent groove is precisely controlled, and auxiliary

vent grooves are densely arranged along gas-trapping areas such as weld lines and corners. This ensures timely discharge of

air and foaming gas in the cavity, preventing cell collapse.

Conformal cooling channels maintain a reasonable distance from the cavity surface, and when combined with 3D-printed

profiled channels, they improve temperature control uniformity, providing a stable environment for cell growth.

The ejection system must adapt to the characteristics of foamed products: the draft angle is set to 1°-2° for flexible materials

like PP, and 2°-3° for rigid materials like PC; ejector pins undergo hardening treatment to enhance hardness and smoothness,

reducing ejection scratches.

2. Process Parameter Debugging: Multi-Variable Synergistic Optimization

2.1 Basic Parameter Calibration

Injection temperature is adjusted based on material properties: 180-220°C for PP systems and 240-280°C for PC systems.

Temperature fluctuation is controlled within ±1°C to ensure stable dissolution of supercritical fluids.

The mold uses gradient temperature control: the cavity side temperature is slightly higher to allow sufficient cell growth time,

while the core side temperature is lower to accelerate surface solidification, with real-time regulation via a PID system.

Injection pressure is set to 20-50 MPa, sufficient to fill the cavity without inhibiting cell growth; back pressure is 5-15 MPa,

ensuring thorough mixing of the melt and supercritical fluid to form a homogeneous melt-gas system.

2.2 Foaming Parameter Matching

The injection amount of supercritical CO? is adjusted according to lightweight targets—insufficient injection results in negligible

lightweight effects, while excessive injection easily causes oversized cells or product cracking. The pressure drop rate must exceed

100 MPa/s to promote the formation of numerous uniform nuclei and achieve fine cell structures.

Packing control differs significantly from traditional injection molding: while traditional molding relies on packing for shrinkage

compensation, prolonged packing in microcellular molding compresses cells, so packing time must be reduced by 30%-50%.

This ensures dimensional accuracy while leaving sufficient space for cell growth. Parameter optimization via orthogonal

experiments can stabilize product tolerance at a precision level.

3. Mass Production Conversion and Quality Control

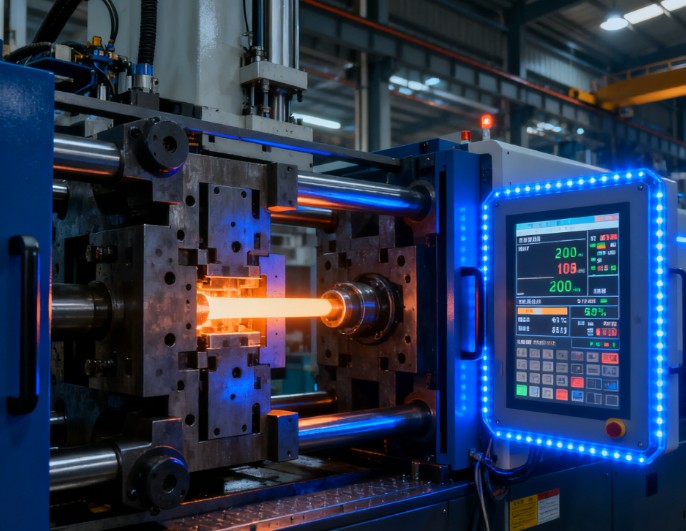

3.1 Equipment and Production Line Setup

Injection molding machines must be equipped with dedicated screws with a compression ratio of 2.5:1-3:1 to enhance shear

mixing and ensure uniform integration of the melt and gas.

Pressure sensors with 0.1 MPa precision are installed at key cavity positions to monitor pressure fluctuations in real time;

temperature sensors track temperature changes, providing data support for parameter optimization.

The production line humidity is controlled at 40%-60%—excessive humidity reduces cell uniformity. A dehumidification system

is optionally equipped for dual dehumidification of raw materials and the environment.

3.2 Defect Prevention and Maintenance

Surface silver streaks can be resolved by improving gate smoothness and optimizing the venting structure, with a remediation

rate of over 90%.

Cavity wear is regularly inspected: when roughness exceeds Ra 0.8 μm, polishing and repair are performed promptly. Introducing

digital twin technology to simulate die operation enables predictive maintenance, reducing unplanned downtime by 20%-30%.

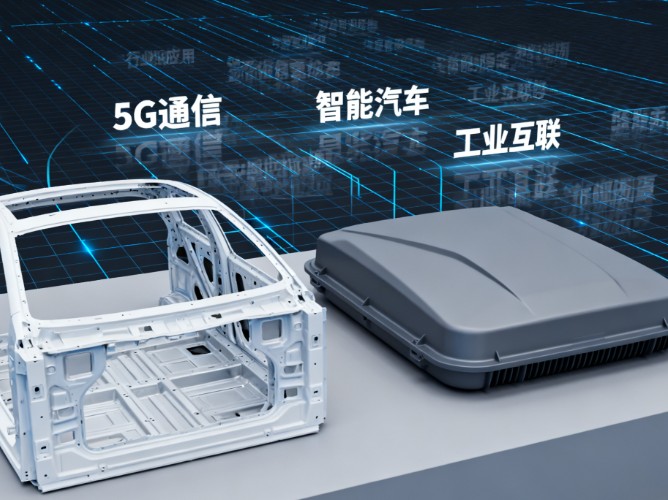

4. Typical Application Verification

In the automotive sector, door panel frames for the Volkswagen MQB platform, molded with microcellular dies, achieve a 22%

weight reduction while meeting mechanical performance requirements, lowering vehicle fuel consumption and material costs.

In the electronics and communications field, microcellular dies used for Huawei 5G base station antenna covers reduce the dielectric

constant by 0.3-0.5, improving signal transmission efficiency, and control warpage within 0.5 mm/m to ensure assembly precision.

These cases confirm the practical value of microcellular injection molding dies, whose technical solutions accurately align with the

lightweight and precision development needs of high-end manufacturing, providing core support for industrial upgrading.