9 Injection Molding Processes: A Concise Overview

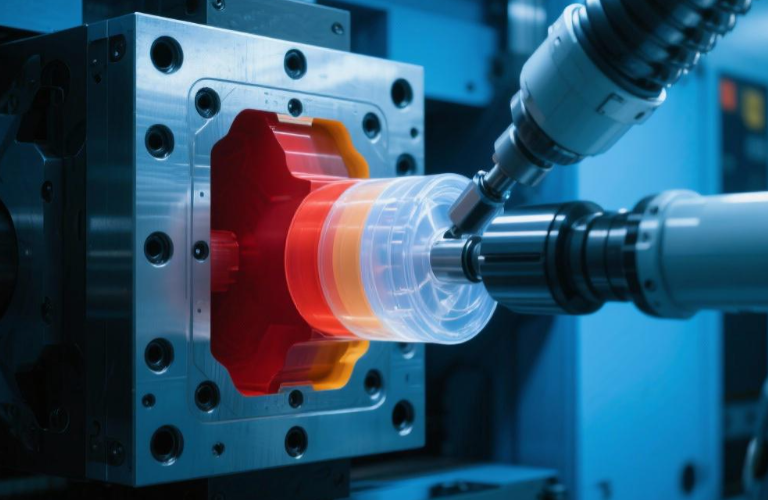

Introduction

As a core modern plastic manufacturing process, injection molding is used in daily necessities, electronics, automotive and aerospace. It injects molten plastic into mold cavities under high pressure for cooling and solidification. This article outlines 9 mainstream processes, their key features and future trends.

1. Conventional Injection Molding (Basic)

Principle: 4-step process (heat pellets to melt: PP 180-220℃, ABS 220-260℃; inject at 50-150MPa; cool (40%-60% cycle); eject).

Features: Fits all thermoplastics; mass production (1-10 cycles/min); ±0.1-0.5mm tolerance.

Applications: Plastic tableware, phone frames, toy casings.

2. Two-Color Injection Molding (Multi-material/Color)

Principle: 2 injection cycles with a dual-unit machine and rotatable mold; fuses two plastics (e.g., rigid ABS + soft TPE).

Features: No post-assembly (30% fewer steps); 80%-90% bonding strength vs. single material.

Applications: Two-color keyboard keys, automotive steering wheels, baby bottles.

3. Insert Injection Molding (Composite Reinforcement)

Principle: Fix inserts (metal/ceramic/fiberglass) in molds; inject plastic to wrap and bond.

Features: Metal inserts boost tensile strength by 2-5x; conductive inserts enable conductivity.

Applications: Circuit board copper nuts, automotive plastic bracket steel inserts.

4. Microcellular Injection Molding (Lightweight)

Principle: Supercritical fluid (CO?/N?) creates 10-100μm microbubbles (10?-1012/cm3) in molten plastic.

Features: 10%-30% weight reduction; 20%-40% lower injection pressure; 50% less internal stress.

Applications: Automotive door panels, aerospace lightweight parts.

5. Gas-Assisted Injection Molding (Hollow)

Principle: Inject 50%-90% plastic; add high-pressure nitrogen (5-30MPa) to form hollow channels.

Features: 15%-40% less plastic; >95% shrinkage elimination; fits uneven walls (ratio >3:1).

Applications: Automotive dashboards, washing machine inner tubs.

6. Water-Assisted Injection Molding (Efficient Cooling)

Principle: Uses deionized water (10-40MPa) instead of gas; faster cooling.

Features: 30%-50% shorter cooling time; ±0.2mm hollow tolerance; fits L/D >10:1 products.

Applications: Plastic pipes, automotive fuel pipes (case: 60s→35s cycle, 5%→1.2% defects).

7. Hot Runner Injection Molding (Waste Reduction)

Principle: Heated runners (±2℃ fluctuation) keep plastic molten; no solidified waste.

Features: 15%-50% less waste; 10%-20% higher accuracy (±0.05-0.1mm); fits batches >100,000.

Applications: Medical syringes, plastic bottle caps.

8. Precision Injection Molding (Ultra-tight Tolerance)

Principle: 5-axis mold (±0.005-0.01mm); ±0.1% injection control; real-time monitoring (>100x/sec).

Features: ±0.005-0.05mm product tolerance; uses LCP/PPS.

Applications: Phone camera lenses (±0.002mm); 2023 market: $28B, 8% annual growth.

9. Co-injection Molding (Multi-layer)

Principle: Multiple units inject plastics (e.g., PC+PP, EVOH+PE) for layered structures; >15N/25mm peel strength.

Features: Integrates functions (barrier/flexibility); 45% used in packaging.

Applications: Food packaging films, automotive interior panels.