Basic Knowledge of Injection Mold Structure

Introduction

As a core equipment for plastic molding, injection molds are widely used in automotive, electronics, home appliance and other industries. Their structural design and performance directly determine the quality, production efficiency and cost of plastic products. Mastering basic knowledge of injection mold structure is essential for personnel engaged in mold design, manufacturing and related fields.

1. Basic Structure of Injection Molds

1.1 Mold Base

The mold base is the framework that supports and fixes internal components, mainly including fixed mold plate (mounted on the injection machine's fixed platen), moving mold plate (mounted on the injection machine's moving platen), support plates and spacers. During injection, the moving and fixed molds close to form a cavity; during mold opening, the moving mold moves to take out products. Its size and strength are selected based on product size, shape and injection process requirements.

1.2 Molding Parts

These parts directly determine the shape and size of plastic products, mainly including:

Cavity (Female Mold): Shapes the outer surface of products.

Core (Male Mold): Shapes the inner surface (e.g., holes, grooves) of products.

Auxiliary Parts: Inserts and slides for complex-shaped products.

High precision, hardness and wear resistance are required to ensure product dimensional accuracy and surface quality.

2. Key Systems of Injection Molds

2.1 Gating System

Channels that guide molten plastic from the injection machine nozzle to the cavity, consisting of:

Main Runner: Connects the nozzle to the runner/cavity; designed based on melt fluidity and nozzle size.

Runner: Distributes melt evenly to multiple cavities to reduce pressure loss.

Gate: The smallest cross-section part, controlling melt flow rate and facilitating product-runner separation (types: side gate, pin gate, submarine gate, selected by product shape and appearance requirements).

Cold Slug Well: Collects cold melt at the end of the runner to avoid defects.

2.2 Ejection System

Removes molded products from the cavity, common types:

Ejector Pins: Most used; pushed by the injection machine to eject products from the core.

Ejector Sleeves: Suitable for products with cylindrical holes, avoiding pin marks.

Stripper Plates: Ejects large-area, thin-walled products from the entire core.

Design requires reasonable ejection positions and uniform force to prevent product deformation or damage.

2.3 Cooling System

Controls mold temperature to accelerate melt solidification, using cooling channels with circulating water (or oil for special cases) to dissipate heat. Channel layout is optimized based on product shape, wall thickness and mold structure to ensure uniform cooling and avoid product defects.

2.4 Venting System

Removes air and gas from the cavity to prevent pores, burning or incomplete filling. Vents are set at the parting line or between components; their depth and width are designed to balance venting efficiency and melt leakage prevention. Vacuum venting is used for precision molds.

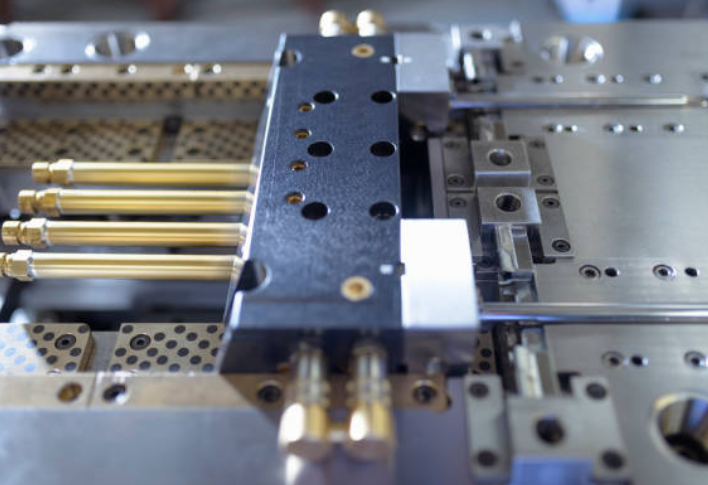

2.5 Guiding and Locating System

Guiding: Guide pins and bushings ensure accurate alignment of moving/fixed molds during opening/closing.

Locating: Locating rings and pins ensure precise mold installation on the injection machine and component positioning during assembly.

3. Key Design Considerations

3.1 Parting Line Selection

Ensure easy product ejection (set at the product's maximum contour).

Facilitate mold processing (prefer flat surfaces).

Avoid visible marks on the product's appearance.

Ensure uniform melt filling.

3.2 Shrinkage Allowance

Plastics shrink during cooling; mold dimensions are enlarged based on material shrinkage data (provided by suppliers) and practical experience to meet final product specifications.

3.3 Strength and Stiffness Calculation

Critical parts (e.g., plates, cores) are calculated to resist high melt pressure, preventing fracture (strength) and excessive deformation (stiffness) that affects product accuracy.

4. Mold Manufacturing Process

4.1 Material Selection

Steel (Most Common): Pre-hardened steel (P20, 718) for high-volume, precision molds; hot-work steel (H13) for hot-runner molds (high temperature/pressure resistance).

Aluminum: Used for low-volume molds.

4.2 Processing Technologies

Mechanical Machining: Turning, milling, drilling and grinding for rough/finish machining.

EDM (Electrical Discharge Machining): For complex cavities/cores via electrical discharge.

Wire EDM: For irregular holes, slots and contours using a moving wire electrode.

4.3 Assembly and Debugging

Assembly: Ensures precise fits (e.g., pin-bushing clearance) for smooth mold movement.

Debugging: Tests the mold on the injection machine, adjusts for defects (e.g., flash, short shots) until qualified products are produced.

5. Mold Maintenance

5.1 Daily Cleaning and Lubrication

Clean plastic residues and oil after production with special cleaners.

Lubricate moving parts (pins, bushings) to reduce friction.

5.2 Regular Inspection and Repair

Check for wear, cracks and blockages (e.g., cooling channels); repair via polishing or part replacement.

Verify locating components for accurate installation.

5.3 Storage

Clean and apply anti-rust oil to molds; store in a dry, ventilated environment.

Support large molds to prevent deformation; inspect regularly.

Conclusion

Injection molds have complex structures requiring professional knowledge in design, manufacturing and maintenance. Mastering these basics enables the production of high-quality molds and products, improving efficiency and reducing costs. With the development of the plastic industry, continuous learning of new mold technologies is necessary to meet market demands.