Types of injection molds for medical consumables and key points of production

Introduction

Injection molds for medical consumables play a critical role in medical product manufacturing, as their quality directly affects the quality and safety of medical consumables. With the rapid development of medical technology, demands for mold types have become more diverse, and production requirements more stringent. Understanding mold characteristics and production key points is essential for ensuring product quality and improving production efficiency.

Main Types of Injection Molds for Medical Consumables

1. Disposable Medical Consumable Molds

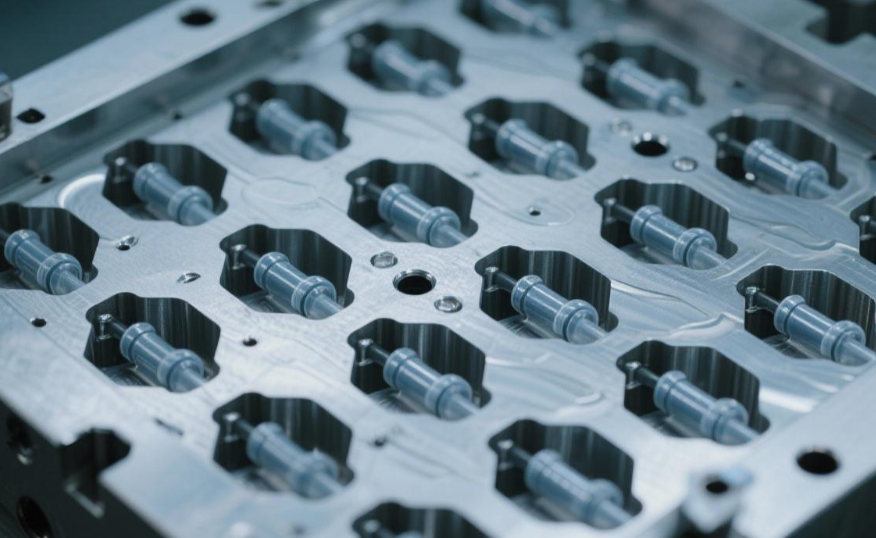

Syringe Molds: Multi-cavity designs (8-cavity, 16-cavity, etc.) are commonly used for high efficiency. Key dimensional tolerance (e.g., syringe barrel inner diameter) is controlled within ±0.02mm to ensure injection accuracy.

Infusion Set Molds: Include drip chamber and tube connector molds. Drip chamber molds require inner surface roughness (Ra) below 0.05μm for smooth liquid dripping; connector molds focus on precision and sealing to prevent leakage.

2. Implantable Medical Consumable Molds

Orthopedic Implant Molds: For artificial joints and bone plates, ultra-precision machining (e.g., 5-axis machining centers) is adopted, with positioning accuracy up to ±0.001mm. Surface treatment (mirror polishing + nano-coating) achieves Ra below 0.01μm to enhance wear resistance and biocompatibility.

Cardiovascular Implant Molds: For stents, molds feature complex micro-structures. Wire diameter tolerance is controlled within ±0.005mm, using micro-machining technology for molding.

3. Diagnostic Medical Consumable Molds

Test Strip Molds: Cavity machining accuracy reaches ±0.01mm to ensure strip dimensional consistency and diagnostic accuracy.

Sampling Swab Molds: Focus on swab head precision and flexibility. Molds ensure uniform fluff distribution and firm rod connection; materials used are non-toxic, odorless, and biocompatible.

Production Key Points of Injection Molds for Medical Consumables

1. Material Selection

Biocompatibility: Materials like S136 steel (after treatment) meet ISO 10993 standards to avoid adverse reactions.

Wear Resistance: Materials like 718H steel (high hardness) suit mass production, extending mold life.

2. Mold Design

Precision Dimensional Design: CAD/CAM and mold flow analysis optimize gate position and runner system. For thin-walled products, hot runner + multi-point gating controls dimensional deviation.

Reasonable Demolding Design: Sliders or lifters are used for undercut products (e.g., medical device housings) to ensure deformation-free demolding.

3. Machining & Manufacturing

Ultra-Precision Machining: Equipment like ultra-precision grinders and EDM machines ensure cavity/core accuracy up to ±0.002mm for small molds.

Surface Treatment: Mirror polishing (Ra up to 0.008μm), nitriding, and hard chrome plating improve hardness, finish, and corrosion resistance.

4. Quality Inspection

Dimensional Inspection: Coordinate measuring machines (CMM) inspect key dimensions (e.g., syringe molds) with accuracy up to ±0.005mm.

Surface Inspection: Optical/electron microscopes check for scratches or pores; atomic force microscopes detect nano-scale defects for high-surface-quality molds.

5. Production Environment Control

Cleanroom Requirement: Class 10,000 or higher cleanrooms with air filtration and personnel decontamination systems prevent mold contamination.

Temperature & Humidity Control: Maintained at 22±2℃ and 45±5% RH to reduce thermal expansion/contraction of mold materials.

Conclusion

Injection molds for medical consumables have diverse types and specific requirements. Strict control over material selection, design, machining, inspection, and environment ensures high-precision, high-quality molds, supporting the medical industry and safeguarding patient health. With advancing medical technology, mold production technology will continue to innovate to meet growing demands.