In precision injection molding, temperature setting is a core parameter, directly impacting part quality, production efficiency, and material performance. This article concisely explains temperature control essentials, material-specific solutions, and smart technology applications.

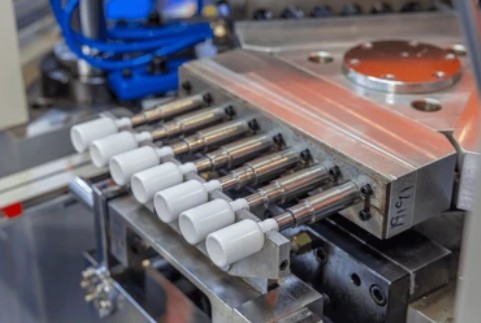

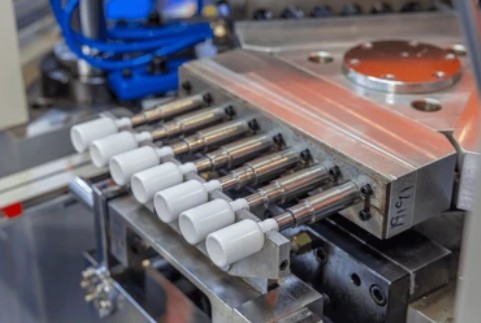

The barrel melts and plasticizes materials, with temperatures set in segments based on material properties:

Amorphous Plastics (e.g., ABS, PS)

Temperature range: Flow temperature to decomposition temperature.

Example: ABS barrel temp: 180–240℃ (feed zone: 180–200℃ for material transport; compression zone: 200–220℃ for plasticization; metering zone: 220–240℃ for melt uniformity).

Crystalline Plastics (e.g., PP, PA)

Temperature range: Above melting point, below decomposition temperature.

Example: PP barrel temp: 190–240℃ (metering zone 20–30℃ higher than feed zone for full melting/crystallization).

For special materials (e.g., glass fiber-reinforced, flame-retardant), increase barrel temp by 5–15℃ to compensate for additive effects.

The nozzle connects the barrel to the mold. Its temperature is 5–10℃ lower than the barrel’s maximum to prevent drooling (leakage) while avoiding solidification.

Mold temp affects cooling and part quality, adjusted by material/part design:

Crystalline Plastics

Set between Tg (glass transition temp) and Tm (melting temp) for optimal crystallization.

Examples: PA66 mold temp: 80–120℃ (enhances strength/stability); PET mold temp: 120–150℃ (boosts crystallinity, reduces stress).

Amorphous Plastics

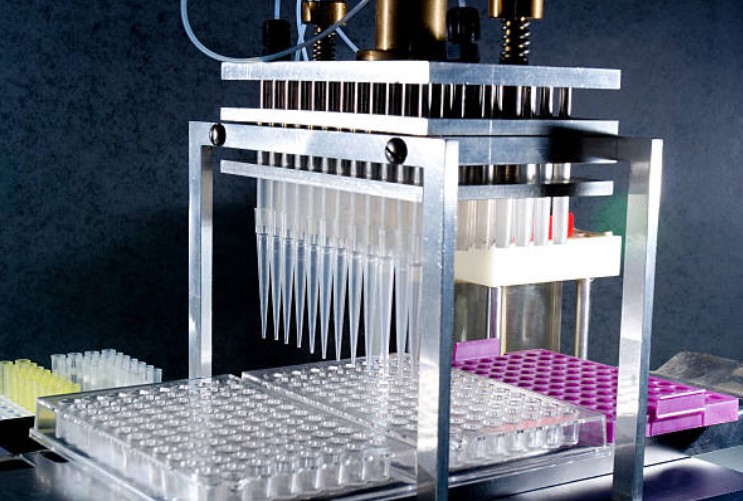

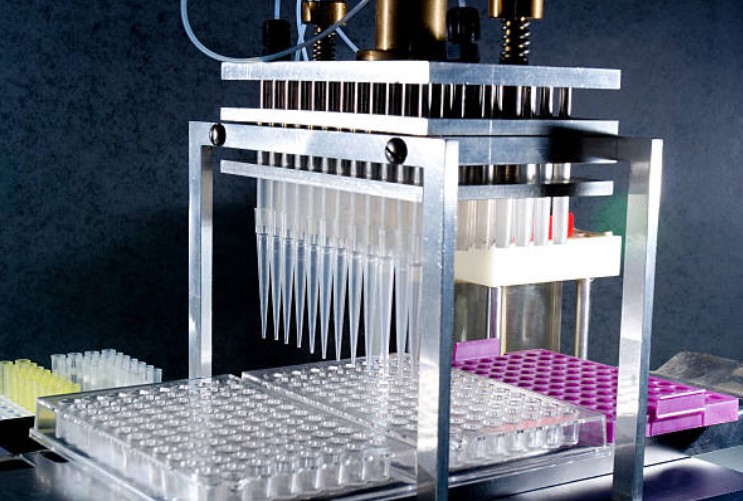

For thin-walled/complex parts (e.g., phone frames), use zone-specific mold temp control (local heating/cooling) to solve filling/deformation issues.

PP

PC

Modern machines use PID auto-tuning to dynamically adjust heating/cooling (e.g., Haitian, Yizumi). Precision: ±0.5℃ (suits optical lenses, micro connectors).

3D-printed conformal cooling channels + multi-zone controllers enable precise temp zoning.

Data platforms integrate historical temps/quality data. AI models recommend optimal temp curves.

Start with supplier-recommended temps (e.g., PA6: barrel 220–260℃, mold 40–80℃). Adjust by part defects (short shot→increase temp; flash→decrease temp) and record “defect–temp” relationships.

Use infrared sensors (mold surface) and melt temp sensors (barrel). Compensate for environmental changes (e.g., seasons) by adjusting mold cooling flow/barrel heating.

Melt Degradation (black streaks/bubbles): Lower barrel temp by 5–10℃ or reduce melt residence time (adjust screw speed).

Uneven Cooling (warpage): Check mold cooling channels or use “variable mold temp” (high temp during injection, low temp during packing) for quick solidification.

Precision injection molding temperature setting requires integrating material science, equipment tech, and practice. Smart control, AI, and customized processes enable breakthroughs in miniaturized, high-performance parts—supporting innovation in electronics, automotive, and medical industries.