Two color mold design and injection precautions

2024-10-10 10:21:11

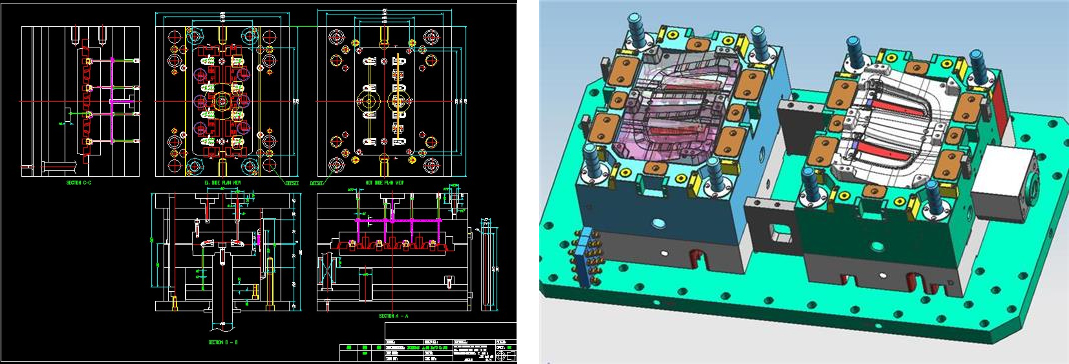

Two color mold

I. Precautions for Two - Color Mold Design

(1) In terms of mold structure

(2) In terms of material selection

(3) Design of hot runner system

II. Precautions for Two - Color Mold Injection - Molding

(1) Injection - molding process parameters

(2) Injection - molding sequence