Customization services for PA nylon plastic parts, POM plastic parts and TPU soft plastic parts are core offerings in the engineering plastics processing field, widely applied in high-end manufacturing sectors like automotive, electronics and medical devices. This article outlines the customization essentials, process specifications and technical trends of these three types of plastic parts, providing precise technical references for customization needs.

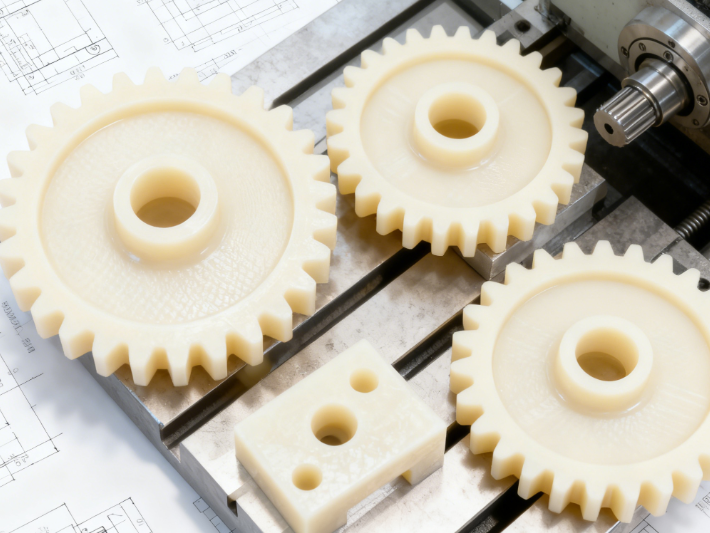

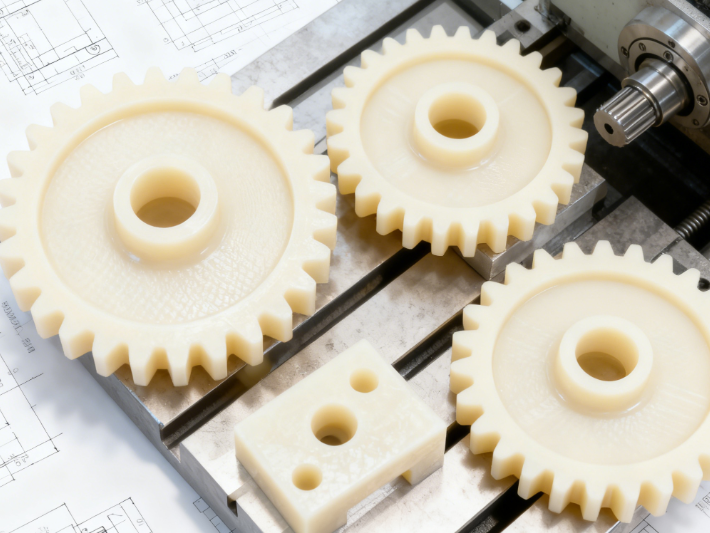

PA Nylon Plastic PartsPA (Polyamide), commonly known as nylon, features outstanding wear resistance, oil resistance and balanced mechanical strength. PA6 has a density of 1.14g/cm3 and a molding shrinkage rate of 0.8%-2.5%, suitable for medium-strength structural components. PA66, with a density of 1.15g/cm3 and a shrinkage rate of 1.5%-2.2%, offers better high-temperature resistance for high-stress applications. Typical customized products include automotive gears, electronic enclosures and mechanical connectors, especially for components enduring long-term friction or oil exposure.

POM Plastic PartsPOM (Polyoxymethylene) excels in self-lubrication, dimensional stability and fatigue resistance. It has a molding shrinkage rate of 1.5%-3.5%, a continuous service temperature range of -40℃ to 100℃, and a tensile strength exceeding 60MPa. Its key advantage lies in high-precision molding, making it ideal for transmission components like gears, sliders and valves, particularly in precision machinery requiring tight dimensional tolerance within ±0.05mm.

TPU Soft Plastic PartsTPU (Thermoplastic Polyurethane) combines rubber elasticity with plastic processability, boasting a density of 1.10 - 1.25g/cm3, a Shore hardness range of A60 - D95, an elongation at break of ≥500%, a low-temperature resistance of -50℃ and a wear resistance five times higher than natural rubber. Customized applications cover seals, shock absorbers and medical catheters, focusing on flexible components demanding flexibility, tear resistance and environmental aging resistance.

Raw Material PretreatmentPA nylon requires drying at 100 - 110℃ for 12 hours to control moisture content ≤0.2% and avoid bubble defects. TPU needs drying at 80 - 90℃ for 2 - 4 hours with moisture content <0.1% to prevent hydrolysis. POM has low hygroscopicity and no pre-drying is needed under normal conditions, but drying at 60℃ for 4 hours is recommended in humid seasons.

Molding Process ParametersPA nylon is injection-molded at 220 - 300℃ with a mold temperature of 40 - 80℃; glass fiber-reinforced grades require 20% higher injection pressure. POM is processed at 180 - 220℃ with a mold temperature of 50 - 90℃, using low-speed and high-pressure molding to reduce shrinkage marks. TPU is injection-molded at 190 - 230℃ with a mold temperature of 20 - 50℃ (≤30℃ for transparent products). All three materials support injection molding and extrusion; 3D printing enables rapid prototyping for complex structures.

Post-processing and Precision ControlPA nylon parts undergo humidification or annealing to stabilize dimensional shrinkage, with key tolerances controlled within ±0.03 - ±0.10mm. POM parts are subjected to low-temperature tempering to eliminate internal stress. TPU parts require gate burr removal, with optional surface texturing for improved feel.

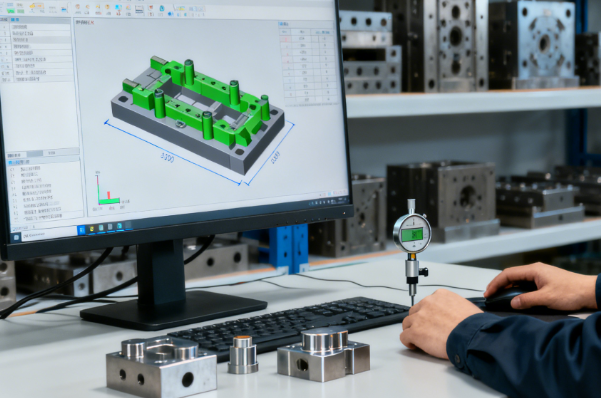

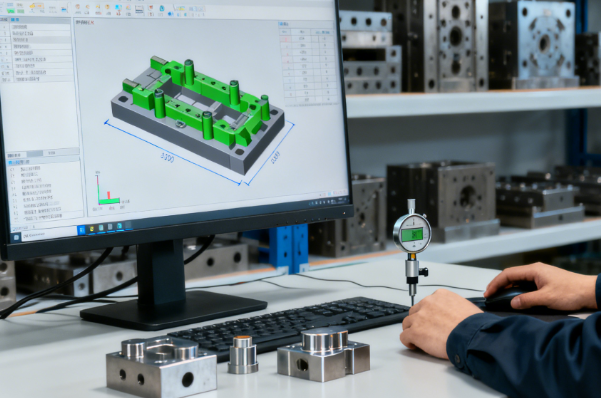

Key Inspection IndicatorsMechanical performance: PA nylon tensile strength ≥50MPa, POM impact strength ≥10kJ/m2, TPU tear strength ≥30kN/m. Dimensional accuracy: Coordinate measuring machines ensure key dimension repeatability ≤±0.02mm. Environmental adaptability: PA retains ≥85% performance after 72-hour oil immersion; TPU resists -40℃ to 80℃ temperature cycles without cracking.

Customization Technology UpgradesMaterial modification includes glass fiber reinforcement/flame retardancy for PA, toughness enhancement for POM, and bio-based materials for TPU, complying with RoHS and REACH standards. Process innovations feature two-shot molding for TPU-PA composites and hybrid 3D printing-injection molding for short-run production. Smart manufacturing technologies like mold temperature closed-loop control and online dimension monitoring improve part consistency.

Industry Application TrendsAutomotive: Integrated customization of lightweight PA parts, precision POM transmission components and TPU shock absorbers. Electronics: Miniaturization (minimum feature size 0.3mm) and TPU transparent parts for wearables. Medical: Growing demand for biocompatible TPU parts meeting FDA and ISO 10993 standards.

Customization of PA nylon, POM and TPU plastic parts hinges on precise material-application matching, refined process control and continuous technological innovation. As high-end manufacturing demands better performance, precision and environmental friendliness, material modification, smart process optimization and application expansion will drive the development of customization services. This article serves as a practical guide for customization communication, production implementation and quality control, facilitating efficient and high-quality plastic part customization.