Rubber products like new energy vehicle seals and rail transit shock-absorbing components are prone to performance failure from ozone erosion and natural weathering. As core tools for assessing rubber anti-aging performance, rubber ozone aging test molds and weathering test molds produce standardized specimens, work with environmental simulation equipment, enable quantitative testing of rubber’s anti-cracking and long-term performance degradation resistance, and support material selection and quality control. The two mold types have clear functions: ozone aging test molds focus on dynamic anti-cracking performance in ozone environments (needing to match tensile conditions); weathering test molds simulate comprehensive climates (sunlight, high/low temperatures, humidity) to detect long-term service performance changes of materials.

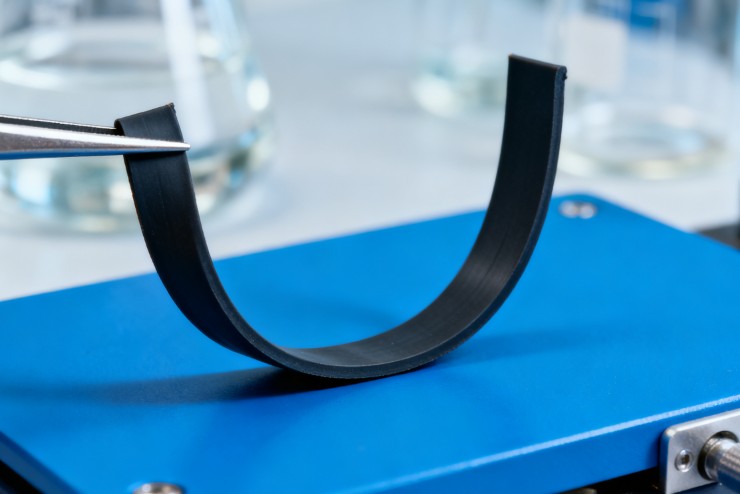

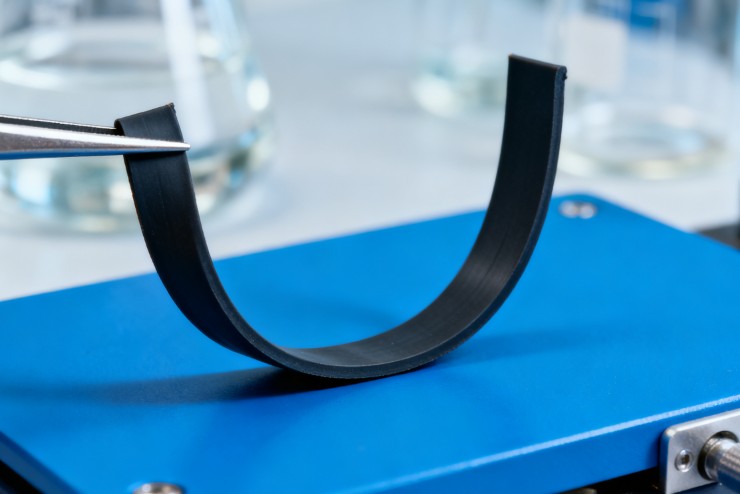

Structural design: Compatible with two industry-standard specimens. Rectangular specimens are 100×10×2mm (tolerances: ±10mm, ±0.5mm, ±0.2mm) with an effective test section ≥40mm. Dumbbell-shaped rubber specimens adopt Type 1 specs (overall length 115mm, narrow section 33mm, both ±0.5mm tolerance) to concentrate stress on the effective area during tension. Micro-exhaust grooves (0.1mm wide, 0.05mm deep) in the cavity discharge vulcanization gas quickly to avoid specimen air bubbles.

Material and precision: Main body uses Cr12MoV alloy tool steel (hardness HRC58-62 after cryogenic treatment). Cavity dimensional tolerance is ±0.005mm, and working surface parallelism error ≤0.01mm per 100mm. Guide pillars are 20CrMnTi alloy steel (fit clearance 0.02-0.05mm) to prevent tensile deviation. Cavity surface has nano-PTFE coating, reducing demolding resistance by 40% and specimen damage rate to ≤0.5%.

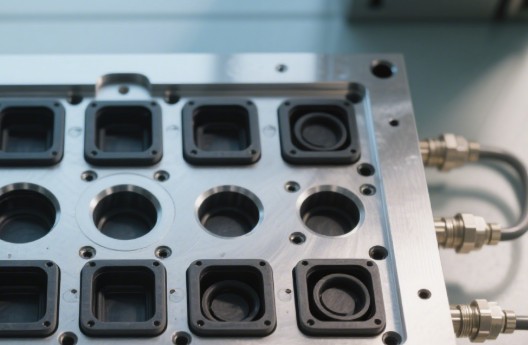

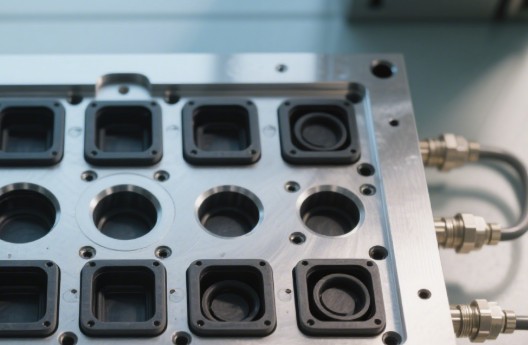

Structural design: Integrated 1-4 cavity layout, compatible with circular specimens (29mm diameter, ±0.5mm tolerance) and square specimens (50mm, ±1mm tolerance), with thickness adjustment range 1.0-10.0mm. Molds have flexible temperature control channels (pre-adjustable -60℃~150℃) for temperature synergy with weathering chambers. A quartz glass observation window is reserved for UV aging to ensure uniform specimen light exposure.

Material and precision: Main body uses H13 hot-work die steel (high-temperature tensile strength ≥1200MPa after quenching/tempering). Cavity surface has 5-10μm Al?O? ceramic coating to resist damp-heat and UV erosion. Key dimensions meet IT7 precision standards (surface roughness Ra≤0.4μm, specimen thickness uniformity deviation ≤0.05mm).

Rubber compound pretreatment: Stand in 23±2℃, 50±10% RH environment for 2-24 hours to eliminate internal stress.

Mold preheating: Ozone aging molds preheated to 60-80℃; weathering molds to 80-100℃ (adjust by rubber type); hold for 15 minutes for uniform vulcanization.

Vulcanization molding: Apply 10-15MPa pressure with a plate vulcanizer; control temperature at 150±2℃, vulcanization time 10-30 minutes (adjust by rubber formula).

Post-treatment: Place demolded specimens in standard environment for 24 hours before testing.

Equipment adaptation: Ozone aging molds match chambers (volume ≥0.1m3) for stable dynamic stretching frequency (0.5±0.025Hz). Weathering molds adapt to chambers (temperature fluctuation ±2℃, humidity 30%-90%) for simulation precision.

Precision calibration: Check cavity dimensions with standard gauge blocks monthly (grind/repair if deviation >0.01mm). Verify molding precision with standard rubber specimens quarterly (ensure test data repeatability error ≤5%).

Parameter adjustment: Set parameters by standards (e.g., ozone testing: specimen elongation 5%-30% with ±1%-±2% tolerance; UV weathering: specimen center-light source distance deviation ≤5mm).

Daily cleaning: Wipe cavity with lint-free cloth after use to remove residual rubber; lubricate moving parts with special oil.

Periodic maintenance: Check coating integrity after 200 moldings (re-spray PTFE if worn); conduct annual heat treatment to relieve stress and prevent deformation.

Storage specifications: Apply anti-rust oil when idle; store in dry environment (20±5℃, RH ≤65%) to avoid ozone-induced corrosion.

Intelligent collaboration upgrade: Molds now link parameters with environmental test equipment. Integrated ±0.1MPa precision temperature/pressure sensors collect real-time molding data, feed back to chambers to correct specimen preparation deviations, and improve efficiency by over 20%. Some high-end molds have micro-strain sensors to monitor stress distribution and predict defects.

Cross-standard generalization: With GB-ISO alignment, universal modules are key. Ozone aging mold tensile fixtures adapt to GB/T 13642/ASTM D1149; weathering mold cavity module switching takes <30 minutes (reducing multi-spec cost). Key precision is unified to IT7 for consistent cross-lab data.

Full-life cycle environmental optimization: Recycled Cr12MoV is used; laser engraving reduces scrap. Ceramic anti-adhesion coatings replace release agents (cutting VOCs by 70%). Mold service life extends from 30,000 to 50,000+ cycles to reduce solid waste, aligning with green manufacturing.

The two mold types’ technological iteration shifts rubber aging testing from "empirical judgment" to "precision quantification". In practice, select molds by standards and material properties, and ensure test data’s production guidance value via standardized operation and regular maintenance.