Technical Characteristics and Applications of Precision Rubber Test Molds, Low-Temperature Weather-Resistant Rubber Test Molds, and High-Temperature Rubber Test Molds

The quality verification of rubber products relies on a diversified system of rubber test molds, including ozone-resistant aging rubber test molds for outdoor durability evaluation, dynamic fatigue rubber test molds for verifying reliability under dynamic conditions, and oil-resistant corrosion rubber test molds for chemical scenario adaptation. Among these, precision rubber test molds, low-temperature weather-resistant rubber test molds, and high-temperature rubber test molds are key equipment for high-precision and extreme temperature applications, directly determining the accuracy of performance evaluation for core rubber components in automotive, medical, and new energy fields. This article focuses on their technical characteristics, production scenario adaptation, and technical trends.

1. Technical Characteristics and Production Applications of Core Rubber Test Molds

1.1 Precision Rubber Test Molds

1.1.1 Core Function

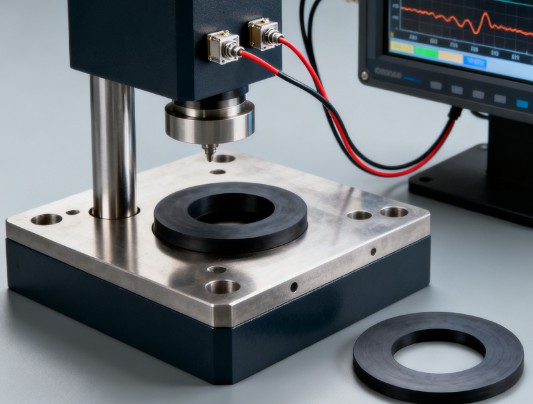

Used to produce high-precision rubber samples for testing tensile strength, elongation at break, and sealing performance, especially for precision rubber components (e.g., medical catheter seals, electronic device gaskets). It ensures sample dimensional tolerance ≤ 0.01mm to avoid test data deviation.

1.1.2 Key Parameters & Design

Precision control: Mold cavity tolerance ±0.005mm, surface roughness Ra ≤ 0.2μm; 5-axis CNC machining and 100% CMM inspection ensure consistency.

Structural optimization: Nano-release coating (e.g., PTFE) for sticky materials; 3–4 evenly distributed feed ports for uniform filling.

1.1.3 Production Adaptation

Suitable for medical silicone seals (φ5±0.005mm inner diameter, meeting ISO 80369-7) and ultra-thin electronic gaskets (0.1±0.005mm thickness).

1.2 Low-Temperature Weather-Resistant Rubber Test Molds

1.2.1 Core Function

Simulates -60℃ to -20℃ environments to produce samples for testing elastic recovery, low-temperature brittleness, and compression set, adapted for cold-chain logistics and polar vehicle components.

1.2.2 Low-Temperature Design & Control

Material selection: 1Cr18Ni9Ti stainless steel (cold toughness); copper alloy inserts (thermal conductivity ≥380W/(m·K)).

Temperature management: ±1℃ control accuracy, 5–8mm polyurethane insulation; 2–3 hours pre-cooling for -40℃ tests.

1.2.3 Production Adaptation

Tests polar vehicle seals (-50℃ for 24h, tensile strength retention ≥80%) and cold-chain gaskets (-30℃, compression set ≤25%).

1.3 High-Temperature Rubber Test Molds

1.3.1 Core Function

Simulates 150℃ to 250℃ environments for testing thermal aging, high-temperature compression set, and thermal tensile strength, adapted for automotive engine compartments and new energy battery packs.

1.3.2 High-Temperature Design & Control

Material treatment: H13 hot-work steel (HRC 48–52, tensile strength ≥1200MPa at high temperature); Al?O? ceramic coating (5–10μm).

Thermal management: Φ6–8mm cooling channels (cooling from 250℃ to room temperature ≤30min); 0.02–0.03mm compensation gap for thermal expansion.

1.3.3 Production Adaptation

Tests engine oil seals (180℃ for 72h, hardness change ≤10 Shore A) and battery seals (200℃ thermal runaway resistance).

2. Technical Trends of Rubber Test Molds

2.1 Intelligent Data Integration

Molds integrate micro-sensors (±0.5℃ accuracy) to transmit cavity temperature and filling pressure data to testing systems, improving data traceability efficiency by over 60%.

2.2 Advanced Material Application

Low-temperature molds: Titanium alloy (TC4) for -80℃ resistance (toughness +40%).

High-temperature molds: Silicon carbide composites (temperature resistance >300℃, weight -35%).

2.3 Modular Design

Interchangeable cavity inserts (φ3–10mm) reduce replacement time from 2h to <30min; quick calibration restores tolerance to ±0.005mm.

3. Key Operational Points in Practice

3.1 Mold Maintenance

Precision molds: Clean with ethanol after use; monthly CMM inspection (repair if deviation >0.008mm).

Low-temperature molds: Dry cavities to prevent rust; quarterly insulation check.

High-temperature molds: Clean cooling channels every 50 tests; re-coat ceramics if wear >2μm.

3.2 Sample Preparation

Precision molds: Use low-viscosity release agent (5–8μm coating).

Low-temperature molds: Maintain cavity temperature ±2℃ during demolding.

High-temperature molds: Insulate for 10–15min after filling to avoid bubbles.

Conclusion

Precision, low-temperature, and high-temperature rubber test molds are critical for accurate rubber performance testing. With intelligent integration, advanced materials, and modular design, they will better meet the needs of extreme-condition performance verification in automotive, medical, and new energy fields, supporting rubber product quality upgrading.