Application and Innovation of Plastic Molds in the Electronic Equipment Field

Amid the booming development of the electronic equipment sector, plastic molds are a crucial manufacturing process, essential for everything from tiny electronic components to large device casings. They determine not only the appearance and dimensional accuracy of electronic devices but also their functionality and production efficiency. As electronic devices trend toward miniaturization, lightweight design, high performance, and multi-functionality, plastic molds continue to innovate to meet these demands.

I. Wide Applications of Plastic Molds in Electronic Equipment

1. Electronic Device Casing Manufacturing

Most casings for smartphones, laptops, and smart speakers are injection-molded. According to IDC, global smartphone shipments reached 1.25 billion units in 2024, with 65% using ABS+PC alloy or PC casings. For example, the curved back mold of Huawei’s Mate series requires a clamping gap within 0.005mm to avoid flash. Lenovo’s IdeaPad series uses integrated palm rest molds, controlling wall thickness tolerance within ±0.1mm to reduce weight by 15%.

2. Electronic Component Packaging

Plastic molds play a key role in packaging chips, resistors, and capacitors. For TSMC’s 28nm chips, QFP (Quad Flat Package) molds achieve a precise 0.3mm pin pitch, with nickel-plated cavities and stepped pressure-holding processes limiting pin deformation to ≤0.02mm. SEMI data shows the 2024 global market for semiconductor packaging plastic molds reached $4.8 billion, with 92% of consumer chips using injection molds—e.g., Xiaomi Band’s main chip mold produces 800 units per cycle with a ≥99.2% yield.

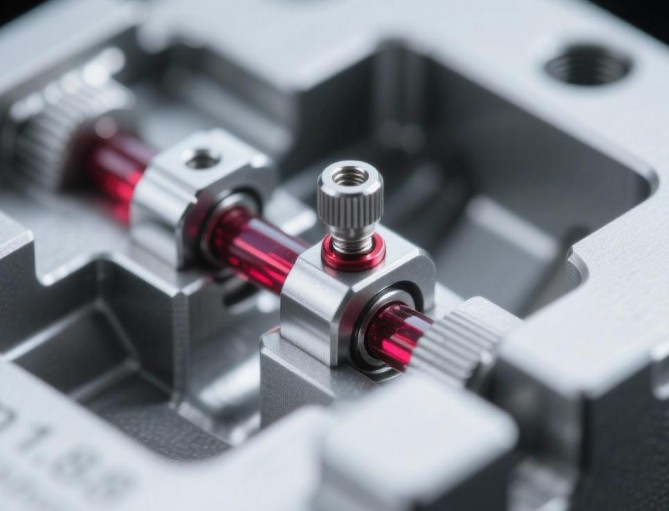

3. Internal Structural Part Manufacturing

Internal parts like brackets and connectors rely on plastic molds. Apple Watch’s antenna bracket mold uses PPS material and micro-foam injection, ensuring a tensile strength ≥80MPa while reducing weight by 20%. Huawei FreeBuds’ charging case connector mold achieves a 0.15mm pin fit gap via wire-cutting (±0.003mm precision), solving plug-in jams.

II. Innovation of Plastic Molds in Electronic Equipment

1. Material Innovation

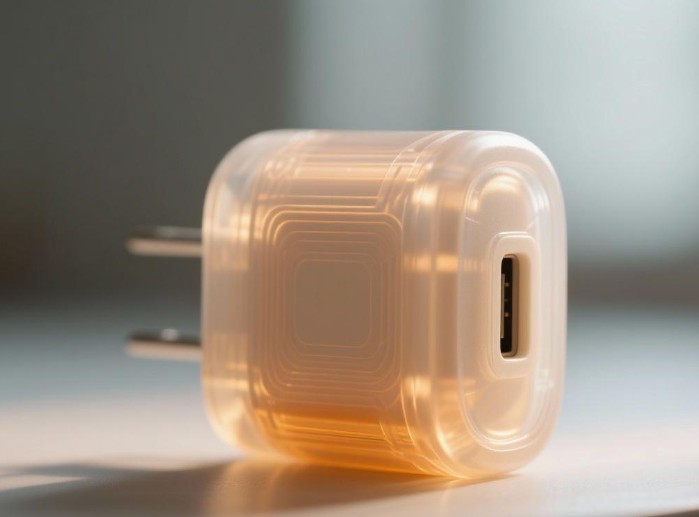

ZTE’s 5G base station antenna mold uses liquid crystal polymer (LCP) with spiral runners, cutting material flow resistance by 30% and achieving a dielectric loss of 0.0028 at 10GHz. A domestic enterprise developed PLA-based charger casings for Honor, optimizing cooling channels to reduce cooling time from 25s to 18s and sink marks from 15% to 2.8%—the casing is fully degradable in 180 days under industrial composting. However, PHA material degrades above 190°C, requiring custom screws (chrome coating + gradient grooves), increasing mold costs by 12–15%.

2. Mold Design Innovation

Simulation-Driven Design: An e-cigarette mold enterprise used Moldflow to identify weld line issues (20% strength loss). Switching to fan gates and 1.2MPa pressure compensation boosted weld line strength to 90% of the base material, cutting test runs from 5 to 2 and shortening development by 32 days.

Miniaturization Design: Sunny Optical’s VR lens bracket mold (2.5mm×1.8mm cavity) uses ruby guide pins (5x more wear-resistant) and piezoelectric injection units (500mm/s speed) to achieve ±0.001mm tolerance. A medical device mold uses magnetic levitation positioning (±0.0005mm precision) to control insert-plastic fit gaps within 0.002mm.

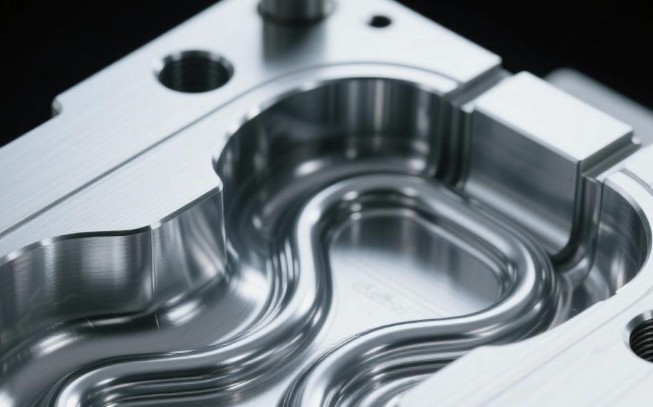

3. Manufacturing Process Innovation

Precision Machining: An automotive electronics enterprise used a DMG MORI NTX2000 5-axis CNC machine to process light guide plate molds, controlling surface seams within 0.002mm and increasing light transmittance from 88% to 92%. 3D-printed conformal cooling channels reduced router casing mold cooling time from 35s to 21s, lifting yield from 85% to 98%.

Intelligent Manufacturing: A Shenzhen mold factory (supplying DJI) deployed sensors to collect spindle load data, using AI (trained on 5,000+ datasets) to extend tool life from 8h to 10–12h, cutting tool breakage from 2% to 0.28% and saving $310k/year. 6-axis robots (±0.02mm repeatability) boosted per capita productivity by 40%.

III. Challenges and Solutions

1. Core Challenges

High-Precision/Complexity Barriers: A 65-inch Mini LED light guide plate mold (for TCL) needs 1.2 million 0.15mm micro-lenses; traditional CNC takes 280h with a 0.5μm PV value (insufficient for ≤0.3μm). Foldable phone hinge molds require 6-way core pulling, with traditional hydraulic systems (0.05s delay) limiting yield to 82%.

New Material Barriers: PEEK (for high-temperature parts) needs 360–380°C injection; traditional heating causes ±5°C cavity temperature difference, leading to 15% cracking. Carbon nanotube-reinforced PP has uneven fiber orientation, causing ±10% thermal conductivity fluctuation.

Environmental Regulations: The EU’s WEEE Directive (2023) mandates ≥85% plastic recycling, but traditional integrated molds only achieve 55%. China’s 2025 regulations require ≤100ppm heavy metals in plastics, increasing mold costs by 8–10%.

2. Solutions

High-Precision Manufacturing: An enterprise used Okamoto ACC-6000 grinding machines (10,000# CBN wheels) to cut Mini LED mold processing time to 120h and PV value to 0.25μm. Servo-driven core pulling (0.005s response) lifted foldable hinge yield to 99%.

New Material Adaptation: A hot oil heating system (±1°C precision) and nickel-phosphorus alloy cavities reduced PEEK cracking to 1.2%. Dynamic pressure holding (0.8–1.5MPa) and barrier screws controlled PP thermal conductivity fluctuation to ±3%.

Eco-Compliance: A laptop enterprise switched to modular middle frame designs (snap connections), lifting recycling from 55% to 88%. It collaborated with BASF to develop low-VOC recyclable plastics, cutting material costs by 5–7%.

IV. Conclusion

Plastic molds are integral to electronic device casings, packaging, and structural parts. Driven by material, design, and process innovation, they advance toward higher precision, eco-friendliness, and efficiency. While challenges like high-precision barriers and environmental rules exist, solutions such as equipment upgrades and supply chain collaboration are available. Future integration with micro-nano processing and intelligent manufacturing will further support the innovation of the electronic equipment industry.