Key Factors Influencing Custom Plastic Part Costs (Streamlined)

Introduction

The cost of custom plastic parts spans the entire process from raw material procurement to delivery. Identifying core cost drivers

at each stage is vital for enterprises to control costs accurately and boost market competitiveness.

I. Material Costs

1. Raw Material Types & Prices

Cost gaps stem from performance:

General-purpose plastics (e.g., PE, PP): Low cost, basic performance, for simple daily items.

Engineering plastics (e.g., PC, PA): Higher cost, better heat resistance/strength, for precision electronics/machinery parts.

Specialized plastics (e.g., PEEK): Far higher cost, complex synthesis, for aerospace/medical fields.

2. Material Utilization

Waste mainly comes from mold design and process control. In injection molding, runners/gates generate waste; poor mold structure

or deviated parameters raise waste rates. Optimizing molds (e.g., hot runner tech) and adjusting parameters cuts waste and related costs.

3. Recycled Material Ratio

Proper use of recycled materials reduces costs but requires quality balance. It suits non-critical products (toys, storage boxes) but

is not recommended for high-performance items (medical devices, optical lenses) to avoid quality risks.

II. Mold Costs

1. Mold Complexity

Cost ties to product structure:

Simple products (flat lids): Low-cost molds with simple design.

Complex products (precision electronic casings with undercuts/thin walls): Molds need sliders/lifters, higher precision, and much

higher costs. Simplifying product design reduces mold costs.

2. Mold Material & Lifespan

Choose materials based on production volume:

Aluminum alloy: Low cost, short lifespan, for small-batch/short-term production.

Ordinary steel: Moderate cost/lifespan, for medium-batch production.

Quenched steel: High initial cost, long lifespan, for large-batch/long-term production.

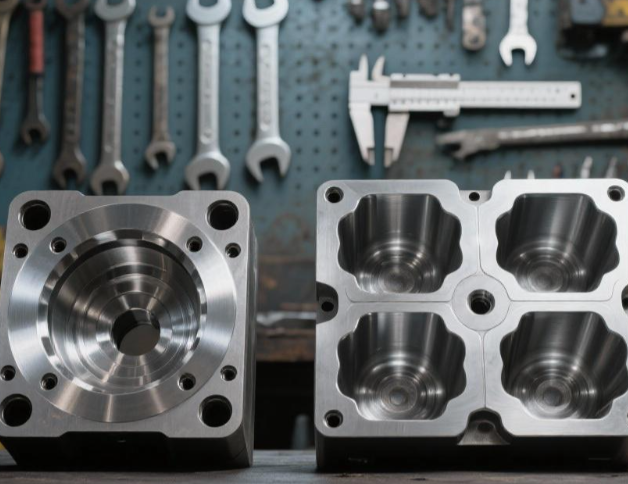

3. Mold Cavity Count

Multi-cavity molds: Higher efficiency but costlier, ideal for large-batch orders (lowers unit mold cost via scale).

Single-cavity molds: Cheaper but less efficient, better for small-batch orders.

III. Processing Costs

1. Molding Process & Equipment

Injection molding: For complex shapes, high equipment investment/energy use.

Extrusion molding: For pipes/plates, low cost/energy use.

Blow molding: For hollow products (bottles), moderate cost. Equipment tonnage matches product size—larger products need costlier,

high-tonnage equipment.

2. Production Efficiency

Shorten cycles to cut unit-time costs: Optimize mold cooling (e.g., cooling channels) to reduce injection molding cooling time. Use

automation (robotic retrieval, auto-inspection) to cut labor time and defect rates.

3. Labor Costs

Tied to automation and regional labor rates. High-labor-cost regions benefit from automated lines, which reduce labor reliance,

costs, and quality issues from inconsistent manual work.

IV. Product Design Factors

1. Complexity & Precision

Complex structures (multi-cavity, thin ribs) and tight tolerances raise production difficulty and defect rates, increasing quality

control costs. Avoid overdesign to balance function and cost.

2. Size & Weight

Larger/heavier products need bigger molds/higher-tonnage equipment and more raw materials, increasing costs. Control size/weight

during design.

V. Order & Production Scale

1. Order Volume

Fixed costs (molds, equipment debugging) spread across products: Small batches mean higher unit fixed costs; large batches lower

unit costs via scale. Integrate similar orders to reduce unit costs.

2. Scheduling Efficiency

Disorganized scheduling causes equipment idleness and frequent mold changes. Use ERP systems for efficient scheduling

(e.g., centralized production of similar products) to cut debugging time and avoid overtime/expedited logistics costs.

VI. Post-Processing & Supply Chain Costs

1. Post-Processing

Basic treatments (single-color silk screening, ordinary painting): Low cost.

Complex treatments (multi-color silk screening, electroplating): High cost. Simplify assembly (fewer parts, simpler processes) to

reduce costs.

2. Supply Chain & Logistics

Stable procurement: Long-term partnerships with large suppliers ensure quality and better bulk prices.

Price control: Monitor raw material prices (affected by crude oil, supply-demand) and lock costs via long-term contracts.

Logistics: Choose sea freight for large/non-urgent batches, air freight for small/urgent batches.

Conclusion

Custom plastic part costs involve interrelated stages: materials, molds, processing, design, orders, post-processing, and supply

chains. Enterprises should optimize across the entire process to control costs accurately and enhance competitiveness while

ensuring quality.