Top 10 New Technologies in the Mold Opening Industry Review

In the wave of digital and intelligent transformation in manufacturing, mold - opening, a core link in product forming, sees

technological iterations deeply impact production efficiency, cost control and product quality. Especially in plastic parts

manufacturing, new tech applications reshape the industry. Here, we focus on the top 10 cutting - edge mold - opening techs,

analyzed for plastic parts production:

1. 3D Printing - Assisted Mold - Opening Tech

3D printing, beyond simple prototyping, integrates deeply into mold - opening. For plastic mold dev, it quickly prints complex

structures like inserts and sliders, replacing long machining cycles. Via SLS, SLA, etc., high - precision mold parts emerge within

24 hours, cutting mold verification cycles by over 40%. It also enables small - batch plastic part production, advancing “mold

dev + sample verification” in parallel to speed product launches.

2. Precision Temperature - Control Hot Runner Tech

For plastic injection molds, intelligent hot runner temp control is key. With distributed sensors and PID algorithms, runner temp

differences stay within ±1℃, ensuring uniform melt filling. Against traditional cold runners, it cuts plastic waste by over 30%,

shortens molding cycles by 25%, and avoids defects like short shots in thin - walled parts (e.g., phone cases), lifting yields to over 98%.

3. Multi - Cavity Mold Balanced Filling Tech

Multi - cavity molds, core to mass plastic part production, long faced filling consistency issues. CAE simulation optimizes runner

and gate designs, keeping melt flow differences under 5% for molds with ≥8 cavities. In auto interiors and home appliance casings,

paired with hot runners and sequential valves, they triple output per cycle, ensuring part dimensional deviations ≤0.05mm and

slashing sorting costs.

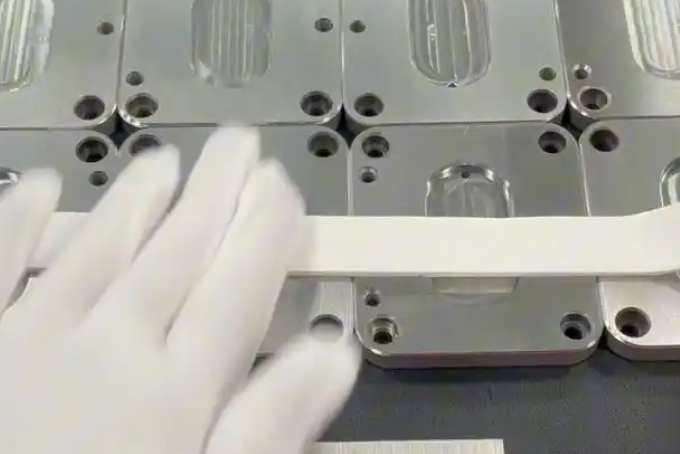

4. Modular Quick Mold - Change Design

For multi - variety, small - batch plastic production, quick mold - change upgrades to “modular + standardized”. Molds adopt

insert - type, unified - interface structures; electric clamps cut change times from 2–4 hours to under 15 mins. In consumer electronics,

charger casing molds switch cavity counts (4/8) fast on injectors, boosting equipment use by 60% for flexible production.

5. Intelligent Mold Health Monitoring Tech

IoT - based systems collect real - time cavity pressure, temp and wear data. In plastic mold production, sensors predict crack risks

(72 - hour warning) and track mold release counts. Applied in an auto plastic part line, repair costs dropped 25%, downtime 60%,

ensuring stable continuous production.

6. Additive Manufacturing Conformal Cooling Channel Tech

Traditional linear cooling in plastic molds causes uneven cooling, long cycles and warpage. Additive manufacturing (SLM) creates

conformal channels, fitting cavity surfaces, boosting cooling efficiency by over 35% and cutting cycles by 20%–30%. In optical and

medical parts, they control dim accuracy within ±0.02mm, solving thin - wall warpage and hitting 99% yields.

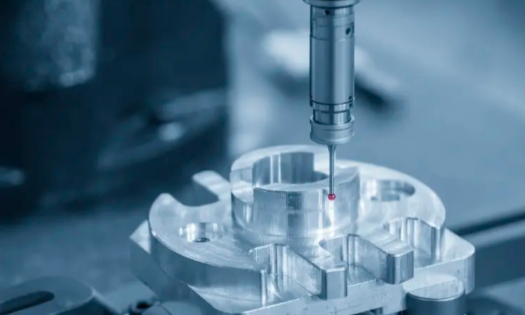

7. High - Speed and High - Precision CNC Machining Tech

Five - axis mills with diamond tools break ground in plastic mold precision machining. Milling at over 20m/min, with Ra ≤0.2μm

roughness, meet optical - grade (e.g., lens mold) needs. AI - assisted programming optimizes tool paths, slashing complex - surface

machining by 30% and ensuring texture consistency for “post - process - free” part assembly.

8. Mold Surface Nano - Coating Tech

To tackle plastic mold sticking and wear, nano - coatings (e.g., DLC) with hardness over 3000HV and friction ≤0.1 cut demolding

force by 40% and double mold life. In PA, POM production, they prevent material adhesion, reduce release agents, and boost part

gloss by 1 level for high - end looks.

9. Virtual Mold Testing and Process Optimization Tech

CAE simulation pre - validates injection processes. Inputting plastic params (e.g., PP, ABS fluidity), it simulates filling, pressure holding

and cooling, optimizing gates and curves. Virtual testing cuts mold debugging by 50%, shortens R & D by 3–4 weeks, and avoids

million - dollar losses from defects in complex parts (e.g., auto intake manifolds).

10. AI - Driven Automated Mold Design

AI learns from mold cases, auto - generating initial plastic mold designs. Inputting product 3D models and requirements (material,

capacity, precision), AI outputs full layouts (runners, cooling, demolding) in 10 mins, lifting design efficiency by 80%. With topology

optimization, molds get 15% lighter and 20% stronger, letting SMEs meet custom needs fast.

These technologies are interconnected and mutually reinforcing. In today’s plastic parts manufacturing landscape, mold - opening

technology is evolving from “experience - based” to “data - driven”, transitioning from “individual mold production” to a

“full - process intelligent manufacturing system”. Mastering these technologies helps companies gain competitive edges in cost

management, quality assurance, and rapid delivery, pushing the entire manufacturing sector toward greater efficiency and intelligence.