The advantages and application scenarios of microfoaming precision injection molding technology

1. Introduction

In the continuous innovation of plastic molding technology, micro - foam precision injection molding technology, integrating high - precision of precision injection and lightweight of micro - foaming, has become a focus in manufacturing, driving industry development.

2. Principle

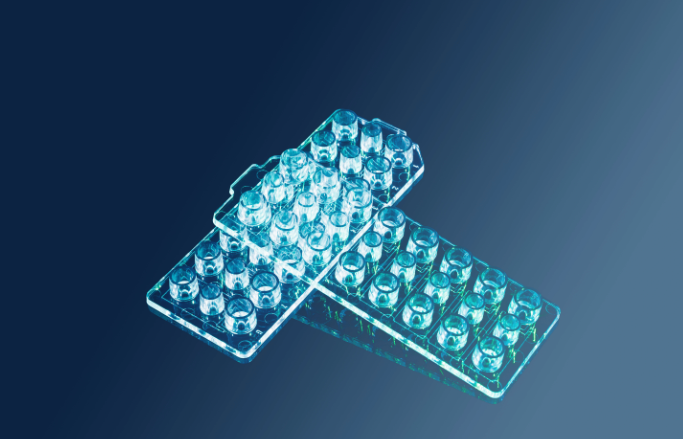

Based on traditional injection, physical/chemical blowing agents are introduced. During injection, tiny bubbles (1 - 100μm) form as the melt is injected into the mold cavity, with parameters like temperature and pressure precisely controlled, endowing products with unique structures.

3. Advantages

(1) Lightweight

For automotive interior parts (e.g., instrument panel skeletons), weight reduces by 20% - 30%. A 10% car weight reduction boosts fuel efficiency by 6% - 8%, aiding energy conservation.

(2) Material Utilization

For large plastic parts, material utilization rises by 15% - 20%, cutting raw material costs (backed by enterprise data).

(3) Performance

Micro - bubbles disperse stress, enhancing impact resistance (e.g., electronic casings absorb impact energy). Heat distortion temperature also increases, improving high - temperature stability.

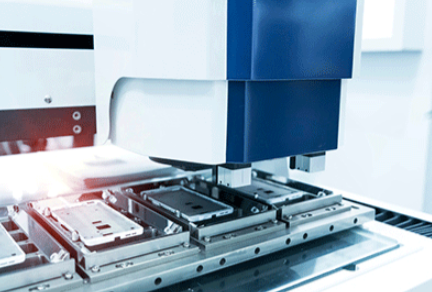

(4) Injection Pressure

Gas reduces melt viscosity and flow resistance, cutting injection pressure by 30% - 50%, extending equipment life and lowering costs.

4. Application Scenarios

(1) Automobile

Interior: Center consoles, door trims, etc., achieve lightweighting and better aesthetics via process adjustment.

Exterior: Bumpers and spoilers gain strength, weight reduction, and impact resistance.

(2) Electronics

Portable Devices: Laptop/tablet casings meet portability and protection needs.

Home Appliances: Refrigerator/washing machine parts become lighter, more durable; micro - foam aids sound insulation in some appliances.

(3) Aerospace

Aircraft interior parts (e.g., seat components) meet fire - proof and aging - resistant standards, reducing aircraft weight for better fuel efficiency.

(4) Packaging

Plastic boxes/pallets see weight reduction, cost - effective transportation, and improved cushioning to reduce product damage.

5. Development Trends & Challenges

(1) Trends

New blowing agents/plastics and optimized molds/processes will enhance foaming efficiency, bubble control, and product quality.

(2) Challenges

High equipment/process control costs and issues like uneven bubbles in special - material/complex - structure products exist.

6. Conclusion

With advantages like lightweighting and high performance, the technology shows great potential across industries. Despite challenges, it will drive manufacturing towards lightweight, green, and high - performance development.