Silicone precision injection molding: Equipment, mold and material requirements

Introduction

In the new era of advanced manufacturing, silicone precision injection molding has gained widespread application in medical,

electronics, and new energy sectors due to silicone’s excellent properties like temperature resistance, aging resistance, and

biocompatibility. Unlike traditional plastic injection molding, silicone’s high viscosity and vulcanization characteristics demand

specific requirements for equipment performance, mold precision, and material control. This article elaborates on key technical

requirements from three core aspects: equipment configuration, mold design, and material selection.

1. Core Requirements for Silicone Precision Injection Molding Equipment

Specialized design for silicone properties distinguishes these machines from conventional plastic injectors. The plasticizing system

uses low-shear screws with a length-diameter ratio of 12-16:1 to prevent premature vulcanization. Screw surfaces, made of

chrome-plated or nitrided alloy, achieve Ra0.2μm roughness to reduce material retention. Temperature control systems require

±1℃ precision, with barrel temperatures set at 40-60℃ for liquid silicone rubber (LSR) and 80-120℃ preheating for high-temperature

vulcanizing (HTV) silicone. Injection systems feature low-speed, high-pressure capabilities (0.5mm/s to 200MPa) for uniform filling of

micro-cavities. Modern machines integrate servo drives and closed-loop control, achieving ±0.5% repeatability with AI-optimized

process parameters. Vulcanization units maintain mold temperatures at 150-200℃ with ±2℃ uniformity, ensuring complete curing.

Advanced models include real-time monitoring of pressure and temperature curves.

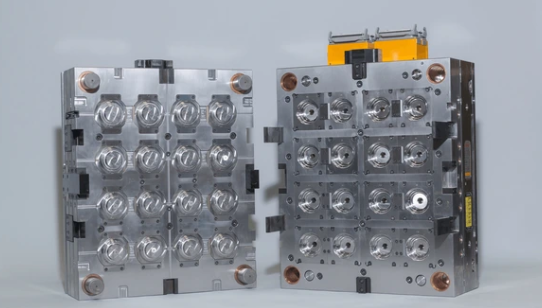

2. Critical Mold Design Requirements

Silicone’s poor flowability and 1.5-3% vulcanization shrinkage demand specialized mold designs. Mold materials use heat-resistant

S136 or H13 steel, hardened to HRC50-55 for dimensional stability. Cavity surfaces achieve Ra0.02μm mirror polishing to reduce flow

resistance. Gating systems feature 20-30% larger runners than plastic molds, with fan or film gates near thick sections. CAE simulation

optimizes runner layouts for complex parts. Ventilation systems include 0.01-0.03mm deep vents at last-fill positions and 0.005-0.01mm

parting line gaps. Modern molds integrate vacuum-assisted venting to minimize bubbles. Precision control incorporates accurate

shrinkage compensation, with critical dimensions held to ±0.01mm. High-precision guide pillars ensure ≤0.005mm fit clearance,

while micro-parts use electroforming or laser machining for micron-level structures.

3. Silicone Material Performance Requirements

Material selection directly impacts product quality, requiring strict performance control. Material types include LSR (good flow, fast

curing) for micro-parts like medical catheters, and HTV (higher strength) for large structural components. New functional silicones,

such as thermal conductive (1-5 W/(m·K)) and conductive (10?3-10?1Ω·cm) variants, expand application boundaries. Key properties

include Shore A 20-80 hardness, ≥7MPa tensile strength, and ≥300% elongation. Temperature resistance ranges from -60 to 200℃

for standard grades, extending to -100 to 300℃ for specialty silicones. Purity standards are critical for high-end applications: medical

grades meet USP Class VI/ISO 10993 with ≤10ppm heavy metals; food-contact grades comply with FDA 21 CFR 177.2600. Batch

stability is controlled within ±5%. Pretreatment includes deaeration for solid silicone and vacuum degassing (≤-0.095MPa for 10-15

minutes) for LSR stored at 25±5℃ to remove bubbles.

In the new era of manufacturing upgrading, silicone precision injection molding demands synergistic optimization of equipment,

molds, and materials. This technology will continue driving advancements in minimally invasive medical devices, flexible electronics,

and new energy sealing applications.