Precision injection molding, a pivotal process in high - end manufacturing, is widely applied in electronics, optics, aerospace, and other industries. Its standardization system is crucial for ensuring product quality and promoting industry - wide standardization. Current national standards for precision injection molding cover equipment, molds, part tolerances, and process specifications, as outlined below:

Scope: Applicable to precision injection molding machines with a clamping force of ≤30,000 kN, defining equipment classification and naming rules.

Key Requirements: Strictly regulate parameters such as injection volume repeatability (≤±0.5%), temperature control, and pressure stability. For example, the parallelism deviation of the clamping system must be ≤0.05 mm/m to ensure dimensional consistency of molded parts.

Testing: Mandate no - load and load - bearing tests, verifying equipment stability through continuous sampling (e.g., 500 cycles) before production.

Dimensional Accuracy: Precision injection molds must meet IT6 or higher accuracy. Critical tolerances for cavities and cores, along with parallelism and perpendicularity (≤0.01 mm), prevent part defects like uneven walls and flash.

Clearance Requirements: Set a precise clearance range (0.005 - 0.02 mm) for moving components (e.g., slides, guide pillars) and limit parting surface roughness (≤Ra 0.8 μm) to avoid material leakage.

Example: Optical lens molds require a cavity surface roughness ≤Ra 0.2 μm, achieved through high - precision grinding and polishing.

Material - based Classification: Categorize plastics into precision groups (e.g., ABS, PC) and general groups (e.g., polyethylene). Precision - grade parts can achieve tolerances of ±0.01 mm (for small sizes), while general - grade parts allow looser tolerances (e.g., ±0.1 mm).

Environmental Compensation: Account for plastic properties like thermal expansion and hygroscopicity. Specify temperature (23℃±2℃) and humidity (50% RH±10%) conditions when defining dimensional tolerances.

Raw Material Handling: Regulate drying processes for hygroscopic materials (e.g., PA, PC). For instance, PA66 must be dried at 120℃ for 4 hours with a dew point ≤ - 40℃ to maintain a moisture content ≤0.02%.

Process Parameter Control: Match injection pressure, holding time, etc., to equipment and molds. Precision parts typically require a holding pressure of 60 - 80% of the injection pressure, with multi - stage control to reduce weld lines and sink marks.

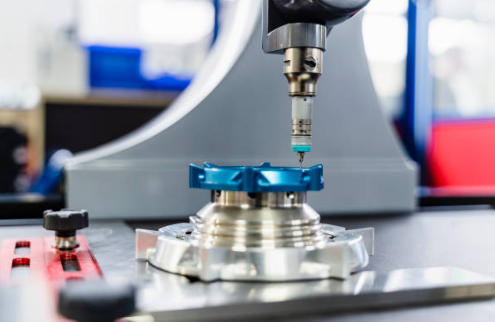

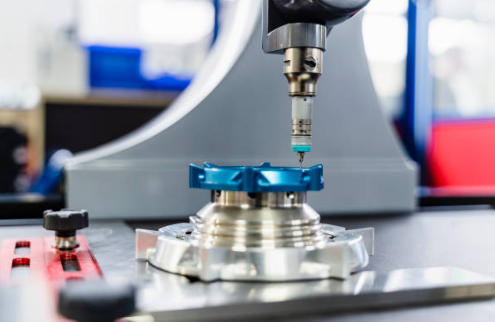

Enterprise Implementation: Enterprises should select compliant equipment, manufacture high - precision molds, and standardize processes. Using tools like coordinate measuring machines and SPC can ensure dimensional compliance.

Future Developments: Upcoming standards will integrate smart manufacturing elements (e.g., IoT - enabled equipment, AI - optimized processes) and green manufacturing requirements (e.g., bio - based plastics, energy - efficient processes), driving the industry towards sustainability.

These national standards serve as a benchmark for precision injection molding. By adhering to these norms, enterprises can enhance competitiveness, while continuous standard updates will propel technological advancements in high - end manufacturing.