SLA and PLA are two different concepts related to 3D printing. SLA is a 3D printing technology, while PLA is a 3D printing material, which is typically used in FDM (Fused Deposition Modeling), another 3D printing technology. The differences between them are as follows:

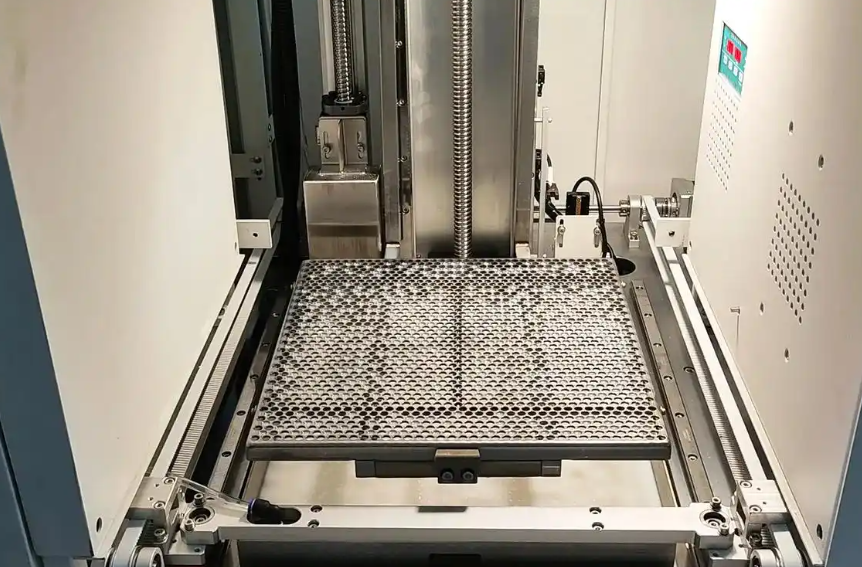

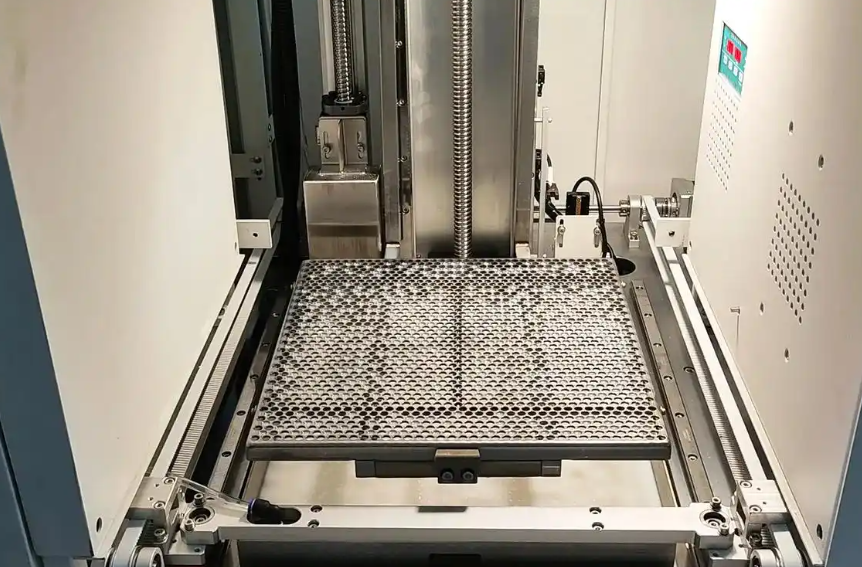

SLA (Stereolithography): It is a photopolymerization 3D printing technology. It uses ultraviolet light to irradiate liquid photosensitive resin and forms objects by curing the resin layer by layer.

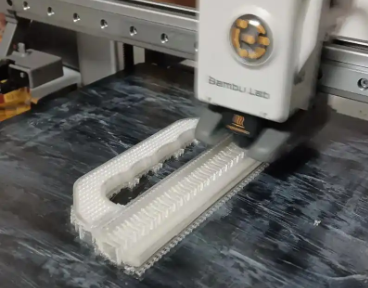

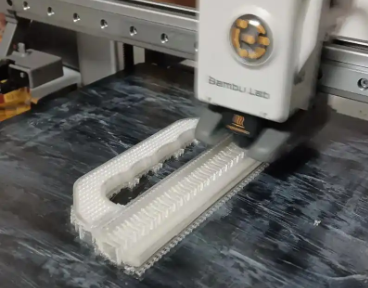

PLA (Polylactic Acid): It is a thermoplastic biodegradable plastic made from lactic acid extracted from renewable resources such as corn starch or sugarcane. In FDM 3D printing, it usually exists in filament form and is deposited layer by layer through a heated extruder nozzle for molding.

SLA: It can achieve very high printing precision, with a smooth and delicate surface. It can print very fine details and complex geometries, making it suitable for making precision models, jewelry, dental models, and other items that require high precision and surface quality.

PLA: Although it can also print relatively fine models, compared with SLA, its precision is usually lower, and there will be certain lines or "stair - stepping effect" on the surface. This difference is more obvious especially when printing small or high - precision objects. However, in some fields where the precision requirement is not extremely strict, such as education, daily supplies, and simple prototype making, the precision of PLA can also meet the needs.

SLA: The printing speed is relatively slow. Since it takes a certain amount of time to cure each layer of resin, and multiple exposure and curing operations may be required during the printing process, especially for complex models, the printing time will be long.

PLA: The printing speed of PLA using FDM technology is usually faster than that of SLA. It extrudes materials by heating and stacks layer by layer quickly. When printing large objects or models with relatively simple structures, it can complete the printing relatively fast.

SLA: Both equipment and material costs are high. SLA printers need to be equipped with high - precision laser systems or ultraviolet light sources, etc. The technology is complex and the price is expensive. Liquid photosensitive resin materials are also more expensive than ordinary PLA materials, and there may be certain material waste during the printing process.

PLA: The PLA materials used in FDM printers are relatively inexpensive, widely available, and come in a variety of colors. At the same time, the structure of FDM printers is relatively simple and the price is more affordable. Especially desktop - level FDM printers are suitable for individuals, families, and small - scale enterprises.

SLA: The printed model usually requires post - processing, such as cleaning in a specific chemical reagent to remove the uncured resin, and then it may also need to undergo secondary ultraviolet curing and other operations to improve the performance and quality of the model. The post - processing process is relatively cumbersome.

PLA: Generally, only simple operations such as removing the support structure (if any) and sanding are required for the printed model. Relatively speaking, the difficulty of post - processing is low.

SLA: It is widely used in industrial design, jewelry manufacturing, dental medicine, precision machinery, and other fields, for making high - precision prototypes, molds, dentures, jewelry wax models, etc.

PLA: It is commonly seen in the education field, used for teaching demonstrations and student work production. In families, it can be used to print some daily supplies, decorations, toys, etc. In product design, it is also often used to make preliminary concept models and simple functional prototypes.