Injection Speed: The injection speed is crucial for the filling efficiency and product quality. Appropriately increasing the injection speed can shorten the filling time, especially for thin-walled products. However, an excessively high injection speed can lead to problems such as air entrapment and flash. The optimal injection speed should be determined through multiple trial moldings based on the product structure, wall thickness, and raw material properties.

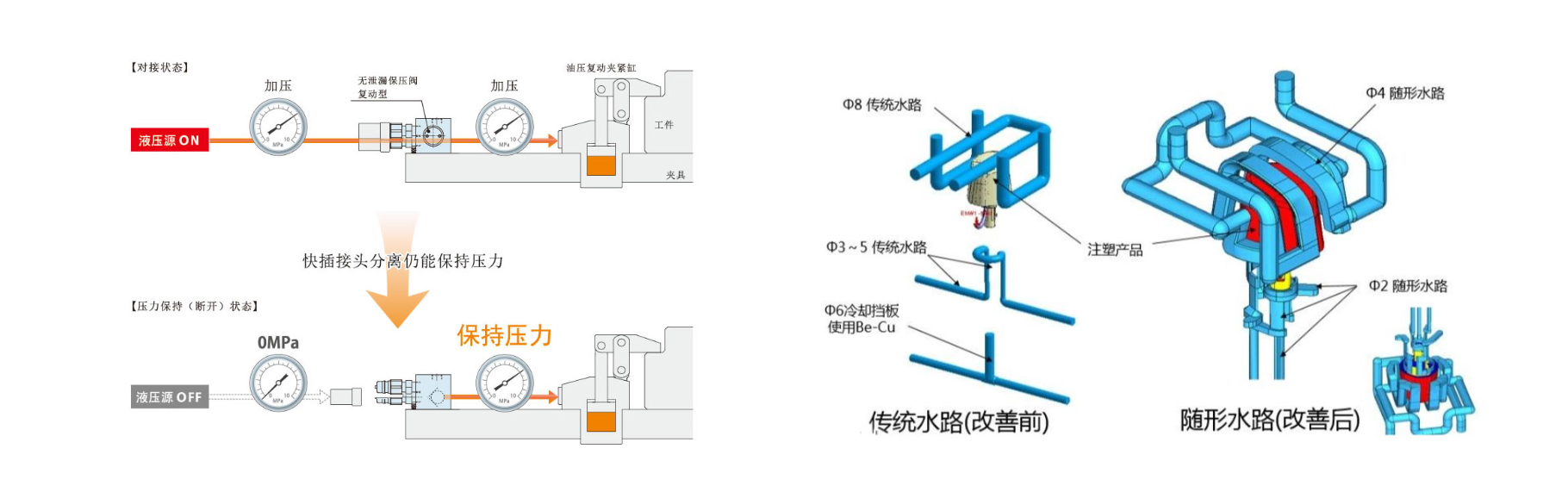

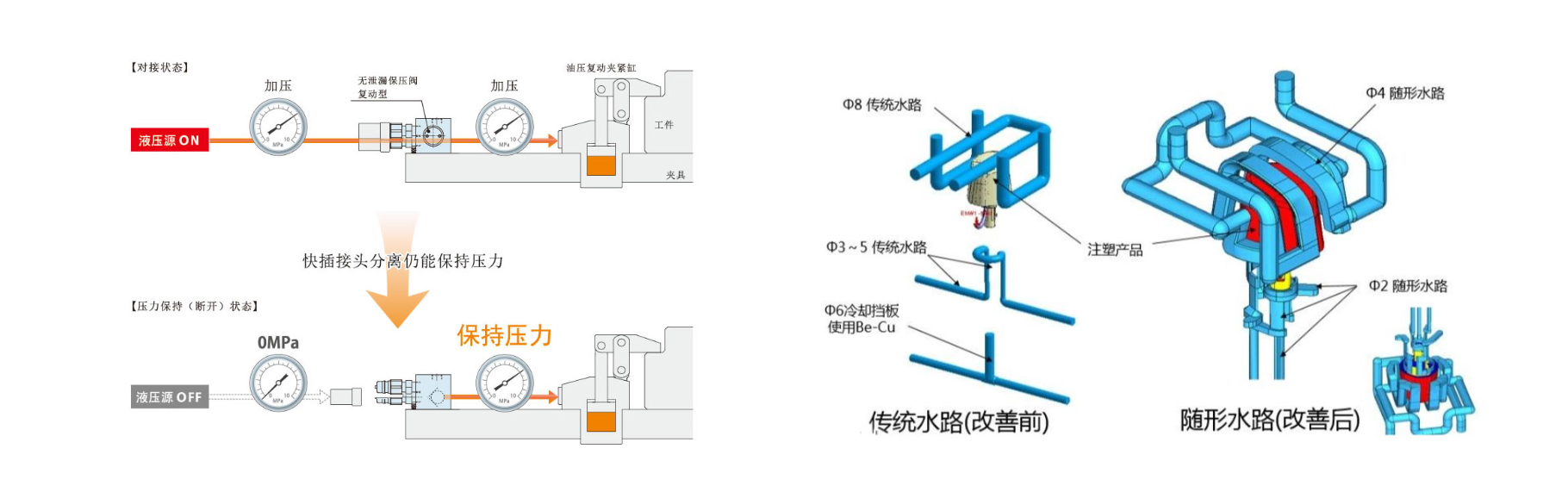

Holding Pressure Time and Pressure: The holding pressure phase is used to compensate for the shrinkage of the plastic during cooling and ensure the dimensional accuracy of the product. However, an overly long holding pressure time will extend the injection molding cycle and cause demolding difficulties, while an excessively high holding pressure will generate internal stress in the product, leading to warping and deformation. The holding pressure time and pressure should be reasonably reduced according to the specific situation of the product through analysis and testing.

Cooling Time: The cooling time accounts for a large proportion of the injection molding cycle, so optimizing the cooling process is essential. Improving the cooling water channel design of the mold, such as increasing the diameter of the water channel and optimizing the layout, can enhance the cooling efficiency and shorten the cooling time. Selecting high-efficiency cooling media, such as special cooling oils, can also promote the rapid cooling of the plastic.

Enhancement of Plasticizing Capacity: When the plasticizing capacity is insufficient, methods such as using a barrier screw, a large-diameter screw, increasing the screw groove depth, increasing the screw rotation speed (except for some shear-sensitive plastics), reducing the back pressure, adopting a hydraulic nozzle seal, pre-plasticizer design, and a holding pressure device can be used to enhance the plasticizing capacity.

Optimization of the Runner System: Shortening the length of the main runner and sub-runner, reasonably reducing the diameter of the runner, and polishing the runner surface can reduce the pressure loss and heat dissipation of the melt, and shorten the flow time. Hot runner molds can avoid the waste of cooling time in cold runner molds, reduce the injection and feeding time, shorten the mold opening stroke, and facilitate the removal of products in multi-cavity injection molding, thus shortening the cycle.

Gate Design: The selection of the appropriate gate type and size has a significant impact on the injection molding cycle. For example, the pin point gate has advantages such as fast melt flow speed and small gate marks. The gate size should be determined according to the product shape, size, and raw material properties to ensure smooth melt filling and avoid problems such as difficult filling or excessive cooling time.

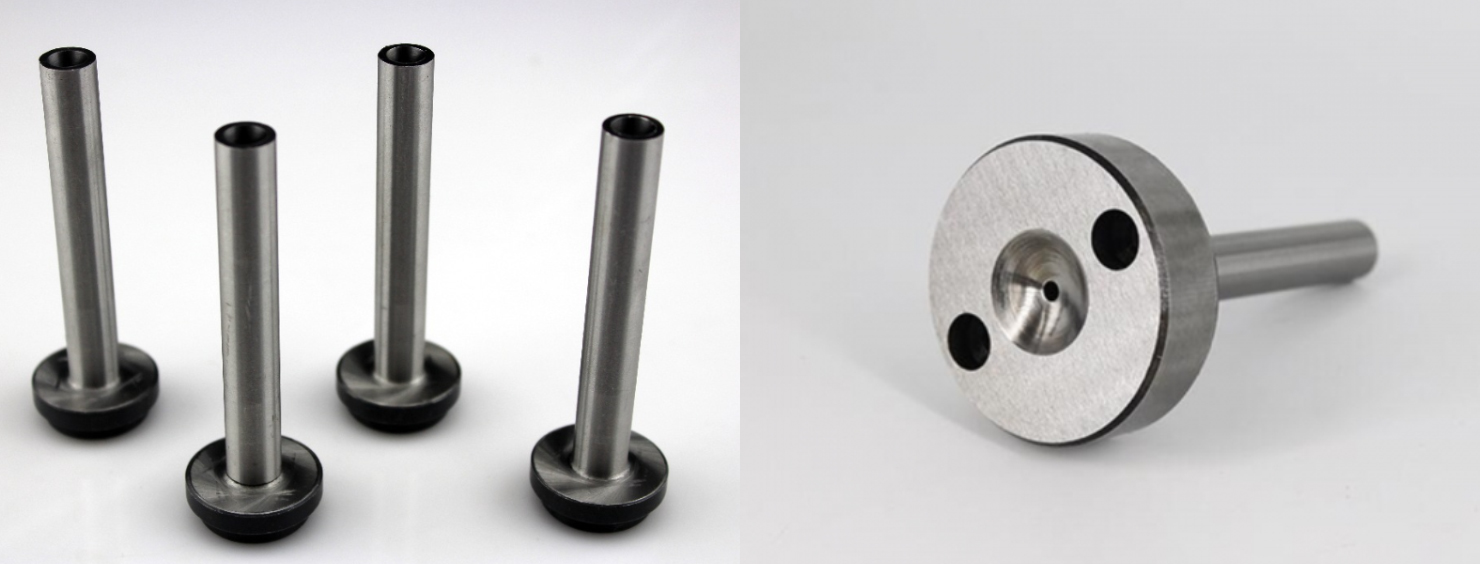

Perfection of the Demolding Mechanism: The demolding mechanism affects the demolding time. Using a reasonable ejection method, such as direct ejection or special demolding structures like inclined ejectors and sliders for products with complex shapes, and selecting the appropriate ejection points can ensure smooth demolding and reduce time waste.