A test spline injection mold is crucial for material evaluation. Here's a concise introduction:

Strength & Hardness: High - strength and hard materials (e.g., H13 steel) with yield strength over 900MPa and HRC30 - 50 are needed to resist deformation and wear during injection and mold operation.

Toughness: To withstand impact loads during mold opening, closing, and operation, preventing cracks.

Thermal Stability: Maintain properties and dimensional stability under plastic melt temperature, with a low coefficient of thermal expansion. P20 steel can work well in 200℃ - 300℃ after heat treatment.

Corrosion Resistance: Resist corrosion from plastic decomposition products and release agents. Stainless steel is suitable for high - corrosion - risk situations.

Processability: Easy to machine through various processes, with appropriate hardness and uniform structure.

Heat Treatability: Improve performance via heat treatment for better comprehensive properties.

High Purity: Low impurity content to ensure mold quality and stability.

By Molding Material

Thermoplastic Mold: For PE, PP, etc., adapting to 150℃ - 300℃ processing temperature.

Thermosetting Plastic Mold: For phenolic resin, etc., withstands high pressure and needs to consider stripping.

Rubber Mold: For natural and synthetic rubber, preventing rubber overflow and ensuring spline accuracy.

By Spline Type

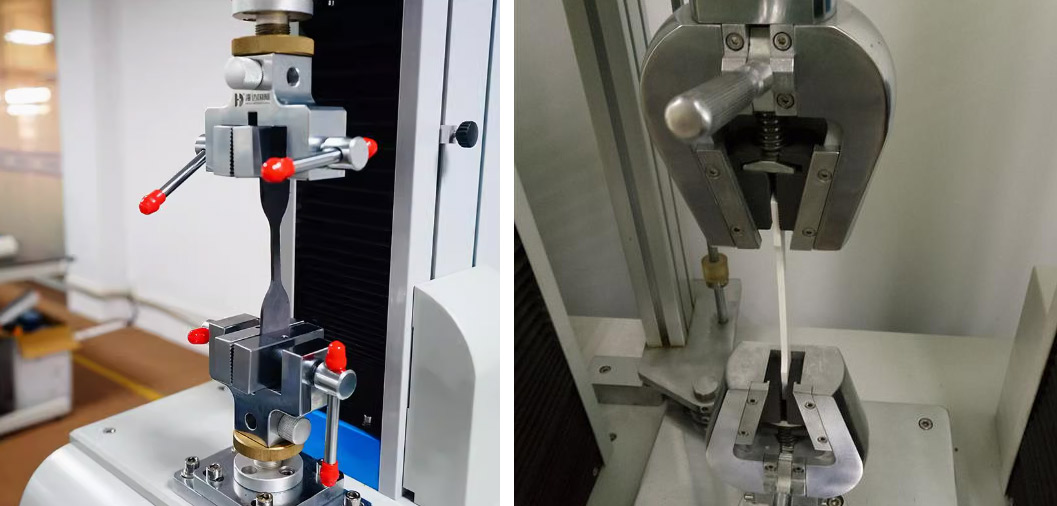

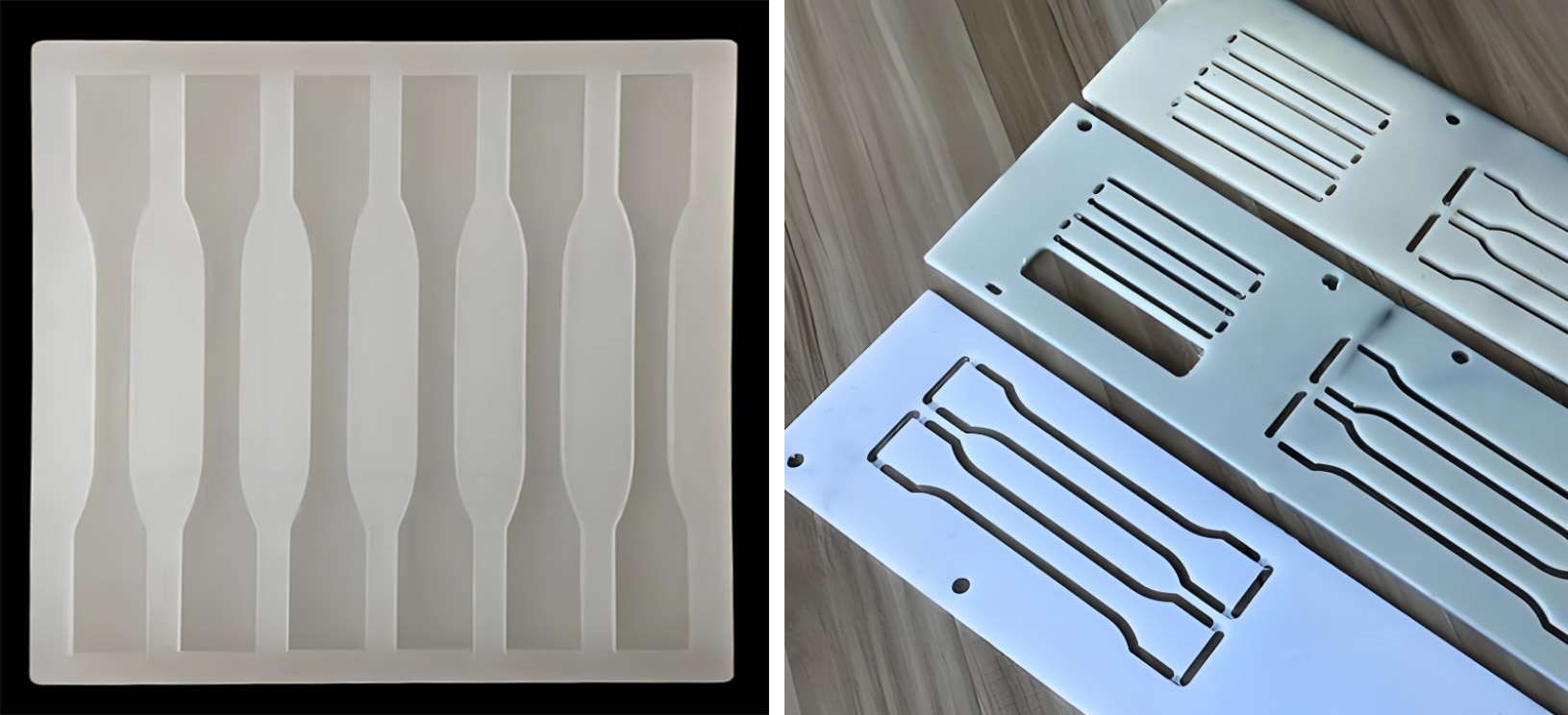

Tensile Test Spline Mold: Manufactures splines meeting tensile test standards with specific dimensions.

Bending Test Spline Mold: Produces splines for bending tests with rectangular - section and standard dimensions.

Impact Test Spline Mold: Creates impact test splines with strict notch requirements.

Cavity: High - precision (tolerance ±0.01mm for aerospace - related splines) and good surface quality (Ra0.8 - Ra1.6μm, higher for optical materials).

Gate System: Moderate size to avoid melt pressure loss and gate marks, and reasonable position to avoid affecting test parts.

Release Mechanism: Flexible design according to spline shape, like push - rod for simple splines and special mechanisms for complex ones.

Blank Processing: Cut raw materials into blank shapes.

Roughing: Remove surplus with CNC machines, leaving 0.5 - 1mm margin.

Finishing: Improve accuracy and surface quality, with strict tolerance and roughness control.

EDM: For complex - shaped parts.

Wire Cutting: For small holes and slots.

Cleaning: Remove impurities from parts.

Inspection: Check parts' accuracy and quality.

Assembly: Assemble parts, ensuring coordination accuracy, e.g., 0.01 - 0.03mm gap for guide post and sleeve.