How much does the wall thickness of plastic parts affect the product?

The wall thickness of plastic parts has a significant influence on product quality.

First, mechanical properties

Step 1: Intensity

Adequate wall thickness provides sufficient strength. If the wall thickness is too thin, plastic parts are prone to rupture

and deformation when subjected to external forces. For example, in some plastic containers that need to withstand a

certain pressure, insufficient wall thickness may cause the container to break during filling or transportation, affecting

the performance and safety of the product. The wall thickness is too thick, although the strength has increased, but it

may lead to internal stress concentration, so that the plastic parts in the cooling process of warping, shrinkage and other

defects, will also reduce the quality of the product.

2. Rigidity

Reasonable wall thickness helps to improve the rigidity of plastic parts. When the wall thickness is too thin, the plastic

parts are easy to bend and deform, which affects the dimensional stability and assembly accuracy. For example, in the plastic

housing of some precision instruments, insufficient wall thickness may cause the housing to fail to provide adequate support

for the internal components, affecting the performance and reliability of the instrument.

However, the wall thickness is too thick may also make the plastic parts too heavy, increase the weight and cost of the product,

and may also affect the appearance quality of the product. Therefore, it is very important to reasonably determine the wall

thickness of the plastic parts. Points to note are as follows:

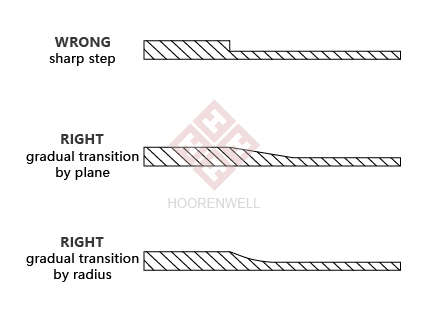

a, the wall thickness of plastic parts should be as uniform as possible, to avoid too thin, too thick and wall thickness mutation,

if the plastic parts require a change in wall thickness, should use a gradual or circular transition, otherwise it will cause uneven

shrinkage of plastic parts deformation, affect the strength of plastic parts, affect the flow of injection molding process problems.

b, the wall thickness of plastic parts is generally in the range of 1-5mm. The most commonly used value is 2-3mm.

c, the minimum wall thickness of commonly used plastic parts and the recommended value of commonly used wall thickness: (mm)

d, try not to design the reinforcement and screw column too thick, it is generally recommended to take half of the thickness

of the body wall is safer, otherwise it is easy to cause appearance problems such as miniature

e, try not to design the parts into a separate plate, the size is very small, otherwise the deformation will lead to uneven parts

Second, molding process

1. Injection molding

During the injection molding process, the wall thickness has an important effect on the molding cycle, shrinkage rate and other

parameters. When the wall thickness is too thin, the flow resistance of the plastic melt in the mold increases, the filling is difficult,

and the defects such as short shot and lack of material are easy to appear. This will not only affect the appearance quality of the

product, but may also reduce the strength and performance of the product.

If the wall thickness is too thick, the cooling time will be extended, the molding cycle will be increased, and the production

efficiency will be reduced. At the same time, the thick wall part is easy to produce uneven cooling phenomenon, resulting in

increased internal stress, shrinkage holes, shrinkage marks and other defects.

2. Blow molding

For blow molded plastic parts, the uniformity of wall thickness is very important. Uneven wall thickness will lead to uneven

force in the blowing process of plastic parts, easy to crack, deformation and other problems.

Reasonable wall thickness design can ensure uniform expansion of plastic parts in the blow molding process, improve product

quality and production efficiency.

Third, appearance quality

1. Surface flatness

The uneven wall thickness will cause the plastic parts to shrink inconsistently during the cooling process, resulting in uneven

surface phenomena and affecting the appearance quality of the product. Especially for some plastic parts with high appearance

requirements, such as automotive interior parts, electronic product shells, etc., the uniformity of wall thickness is directly related

to the grade and market competitiveness of the product.

2. Gloss

The wall thickness also has a certain influence on the gloss of plastic parts. In general, the surface gloss of plastic parts with

moderate wall thickness is better, and the wall thickness is too thin or too thick may lead to a decrease in gloss. This is because

when the wall thickness is too thin, the flow speed of the plastic melt in the mold is faster, and the surface is easy to produce a

rough phenomenon; When the wall thickness is too thick, the cooling time is extended, and the crystallinity of the plastic

molecules is increased, which will also affect the surface gloss.

Fourth, the cost factor

1. Material cost

Too thick wall thickness will increase the amount of material used in plastic parts, thereby increasing the cost of the product.

Under the premise of meeting the performance requirements of the product, the wall thickness should be minimized to reduce

the material cost.

2. Processing cost

Wall thickness also has an impact on processing costs. When the wall thickness is too thin, the processing difficulty is increased,

and higher injection pressure and speed are required, which increases the energy consumption and wear of the equipment,

thus increasing the processing cost. The wall thickness is too thick will prolong the molding cycle, reduce production efficiency,

and also increase the processing cost.