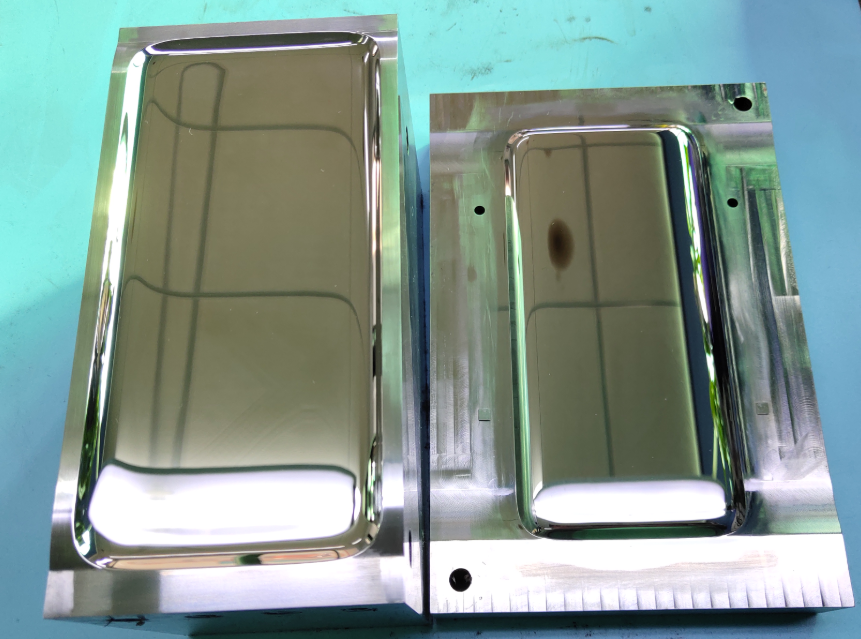

Injection mold surface polishing grade

Die surface polishing grade is assessed according to international standards and requirements. In general, common mold surface polishing grades include the following:

SPI standard: SPI standard is the polishing grade standard developed by the American Plastics Industry Association, which is divided into 12 grades, from A1 to A3 gradually rough. A1 is the highest polishing grade, the surface is very smooth, suitable for demanding optical molds; A3 is the lowest grade, the surface is relatively rough, suitable for general molds and so on.

SPI-A1 Ra0.005-0.01 mirror, with extremely high gloss, can almost reflect objects like a mirror, without any visible flaws, scratches or textures, the surface is extremely flat and smooth, for the appearance of very high requirements for transparent plastic products or optical plastic products mold surface, such as high-precision optical lens mold.

SPI-A2 Ra0.01-0.02 surface gloss is very high, close to the mirror effect. Careful observation under strong light may have very slight traces, but the normal observation of the naked eye can not see the defects, often used in high-quality appearance products mold, such as high-end cosmetics packaging container mold.

SPI-A3 Ra0.02-0.05 has a smooth and glossy surface. Slight texture can be seen, but there is no obvious processing marks, suitable for product molds with high appearance requirements, such as automotive interior parts.

SPI-B1 Ra0.05-0.1 has a smooth surface and a certain luster. With a slight 3000# sandpaper grain, it is used for molds of products with general appearance requirements, such as ordinary electronic product shell molds.

SPI-B2 Ra0.1-0.2 surface is relatively flat, the gloss is general. The processing marks are slightly obvious, and there are slight 2000# sandpaper patterns, but it does not affect the normal use and appearance quality of the product, which is suitable for injection molding products with low appearance requirements, such as some industrial plastic shell molds.

SPI-B3 Ra0.2-0.4 surface has a certain roughness, you can see obvious processing marks, there is a slight 1000# sandpaper grain does not distinguish the direction of processing marks, often used for non-appearance surface or internal structural parts of the mold, such as injection products internal reinforcement, bracket and other parts of the mold.

SPI-C1 Ra0.4-0.8 has a rough surface and obvious processing lines, and is usually used for molds that have no requirements for appearance, such as some internal components of plastic molds that only focus on structural strength.

SPI-C2 Ra0.8-1.6 very rough surface, processing marks are significant, this grade is generally used in the mold does not affect the appearance and function of the product molding of non-critical areas, such as some large injection mold installation base part.

The surface of the SPI-C3 Ra1.6-3.2 is extremely rough, and it is mainly used in parts of the mold that do not need to consider the appearance, such as the auxiliary fixed structure of some molds.

VDI standard: The VDI standard is the polishing grade standard developed by the German Mold Manufacturing Association, which is divided into 15 grades, numbered from VDI 1 to VDI 15, indicating from the smoothest to the roughest. VDI 1 is suitable for high precision molds and VDI 15 is suitable for general molds.

ISO standard: ISO standard is a polishing grade standard developed by the International Organization for Standardization, where ISO 4287 describes the surface shape parameters and ISO 1302 describes the surface roughness parameters. Appropriate grades can be selected according to actual needs.

The following are some common mold surface polishing roughness comparison:

Polishing grade A1 (highest grade) : Under normal circumstances, the surface roughness of the polishing grade A1 mold is generally about Ra 0.05 microns. This highly accurate polishing grade is suitable for demanding optical molds, such as mirror molds.

Polishing grade A2: Polishing grade A2 mold surface roughness is generally about Ra 0.1 micron. This polishing grade is suitable for molds requiring higher precision, such as injection molds, die casting molds, etc.

Polishing grade A3: The surface roughness of the mold with polishing grade A3 is generally about Ra 0.2 microns. This polishing grade is suitable for general molds, such as plastic molds, rubber molds, etc.

It should be noted that different industries and application fields have different requirements for polishing roughness. Some industries may require a higher precision finish grade, while others may require relatively low surface roughness. Therefore, when selecting the mold polishing grade, it is best to refer to the relevant industry standards and customer requirements, and fully communicate with the mold manufacturer to ensure that the requirements are met.