The segmented principle of multistage injection molding

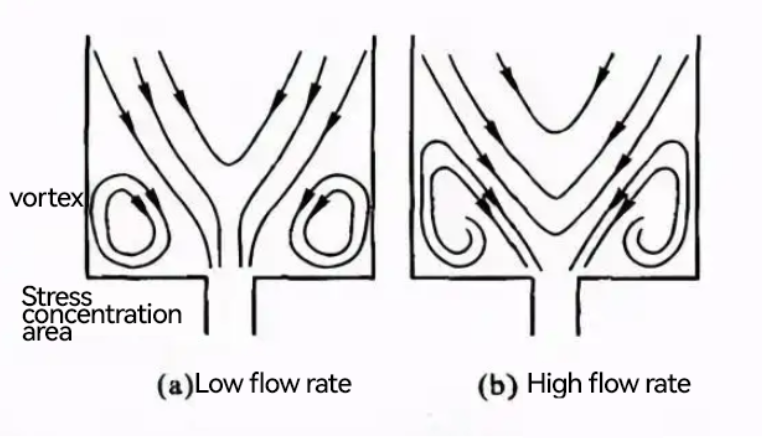

1. Flow characteristics of plastic melt

Screw propulsion phase

First paragraph (starting paragraph)

Generally starting from injection molding, this section is mainly to enable the plastic melt to stably enter the main channel of the mold from the cylinder. Its injection speed is usually slow, mainly to prevent the melt from sputtering at high speeds, resulting in air involvement. For example, for some high-viscosity engineering plastics such as PC (polycarbonate), the starting speed can be set at 10-30% of the maximum injection speed.

Intermediate section

When the melt enters the main stream smoothly, the injection speed is adjusted according to the complexity of the mold cavity and the wall thickness distribution. For simple products with uniform wall thickness, this section can be filled at a relatively high and stable speed to improve production efficiency. For example, for thin-walled simple containers made of PP (polypropylene), the injection speed can be set to a maximum injection speed of 60-80%.

For complex products with wall thickness differences, the speed should be appropriately accelerated in the thin-wall part to ensure that the melt can be quickly filled to prevent short shots. In the thick wall part, the speed should be slowed down properly to avoid defects such as trapped gas and flash. For example, when plastic products with reinforcing bars are injected, the speed can be accelerated at the filling of reinforcing bars (the thin-walled part), while the speed in the thick-walled part of the main body is slowed down accordingly.

Last section

The speed of this section should be gradually reduced so that the melt can smoothly transition to the pressure holding stage. The main purpose is to avoid defects due to sudden pressure changes at the moment of pressure retention switching. The rate of speed reduction should be determined according to the characteristics of the plastic and the requirements of the product, and the speed is generally reduced to the maximum injection speed of 10-30%.

Pressure holding stage

Hold the pressure first section

At the beginning of the pressure holding, the pressure is relatively high, mainly to compensate for the volume shrinkage of the plastic during the cooling process. For crystalline plastics (such as PA-6 polyamide 6), due to its crystallization process will lead to large volume shrinkage, the pressure of the first stage is usually higher, and can be set to 70-90% of the maximum injection pressure to ensure the dimensional accuracy of the product.

Hold the middle section and the last section

As the plastic is further cooled, the holding pressure can be gradually reduced. The middle section pressure can be reduced to 40-60% of the maximum injection pressure, and the final section can be reduced to 10-30%. This can ensure the quality of the product at the same time, reduce the residual stress, prevent the product after the release of warping deformation and other problems. At the same time, the length of the pressure holding time should also be determined according to the wall thickness of the product and the thermal properties of the plastic, the general pressure holding time of thick wall products is longer, and the pressure holding time of thin wall products is shorter.

Second, product structure characteristics

Wall thickness difference

For products with uneven wall thickness, they should be segmented according to the wall thickness distribution. In the thin-walled part, the fast injection speed is used to ensure that the melt can be filled quickly, and to prevent the situation that excessive cooling leads to the increase of melt viscosity and cannot be filled. For example, when injection molding an electronic case with thin-wall and thick-wall connections, the injection speed of the thin-wall part can be 1.5-2 times that of the thick-wall part. In the thick wall part, it is necessary to slow down the speed to avoid trapped gas and contraction marks.

Structural complexity

For products with complex structure, such as products with side holes, backsnaps, reinforcing bars and other structures. When filling parts close to these complex structures, the injection speed and pressure should be adjusted appropriately. For example, when filling the area near the side hole, slow down to prevent the melt from breaking through the hole wall; When filling the reinforcement part, the pressure can be appropriately increased to ensure that the reinforcement can be completely filled.

Appearance requirement

If the product has high requirements for appearance quality, such as no flow marks and no weld marks on the surface. In the filling stage of the surface, to control the injection speed and pressure, relatively low speed and appropriate pressure are generally used to obtain good surface quality. For example, for products with strict appearance requirements such as automotive interior parts, the injection speed of the surface filling stage can be set to a maximum injection speed of 30-50%, while matching the appropriate mold temperature to reduce surface defects.